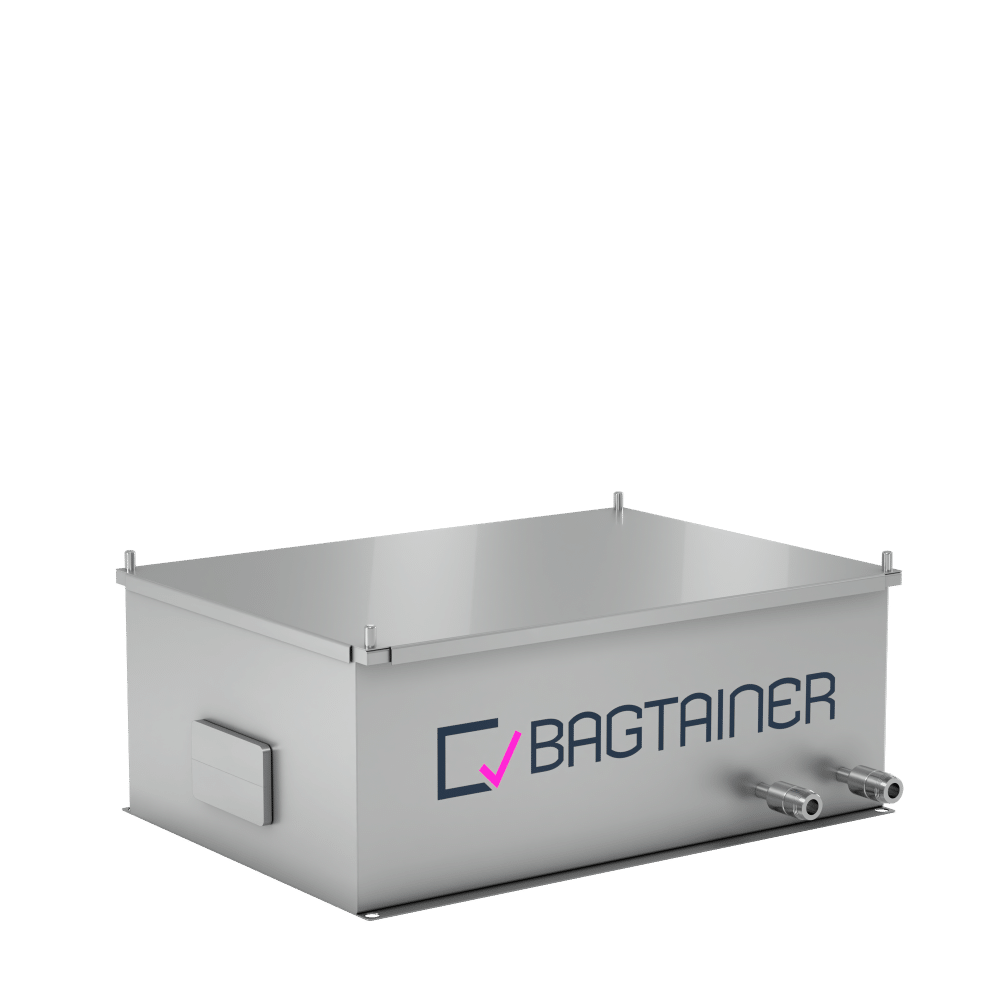

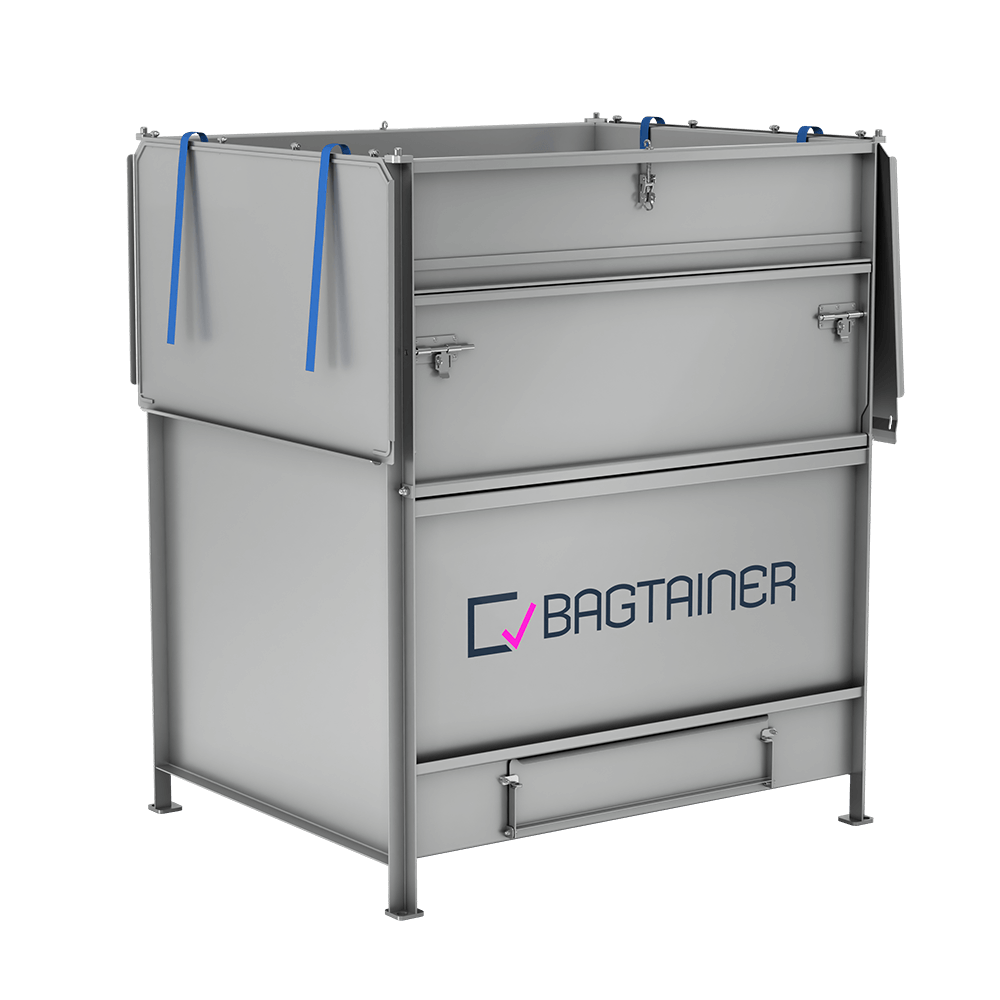

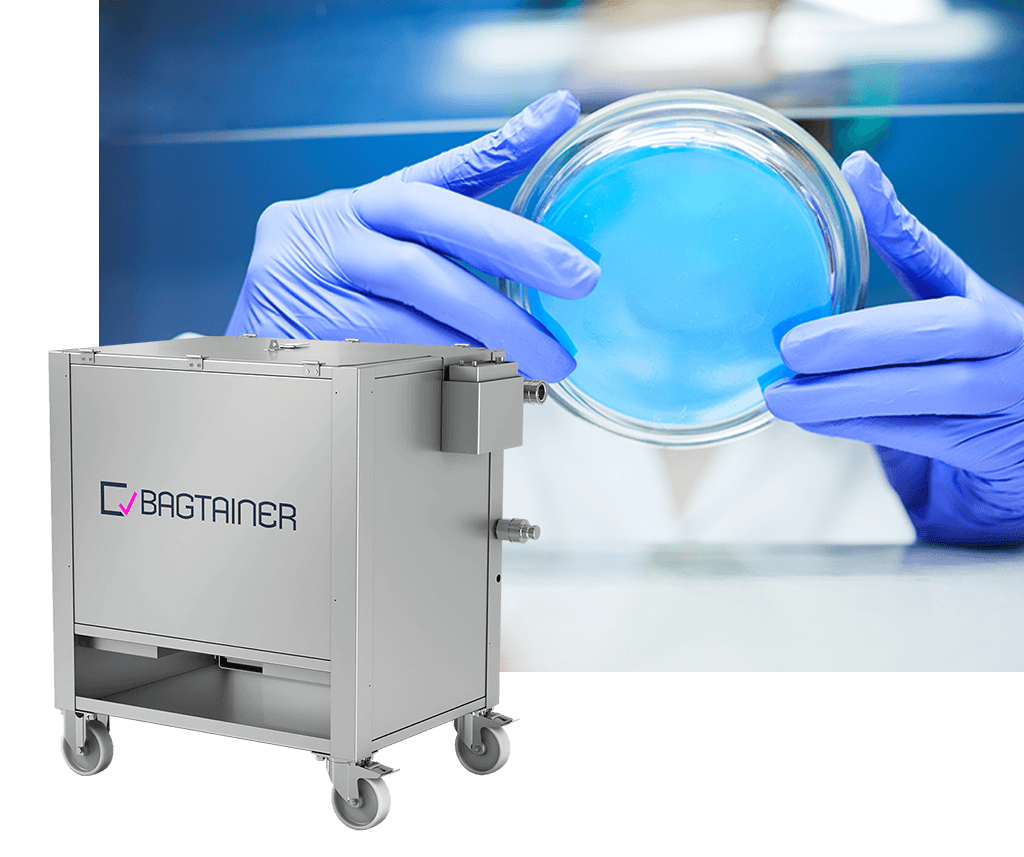

In bioprocess engineering, established processes are constantly optimised. As a result, most of the equipment used in the biotechnological sector has to be adapted – including our bagtainer®. To ensure that they meet all requirements and can be individually integrated into your process, we provide the stainless steel containers with various options on request. These options include, among others, cooling or mixing the contents of your Single-Use Bags.

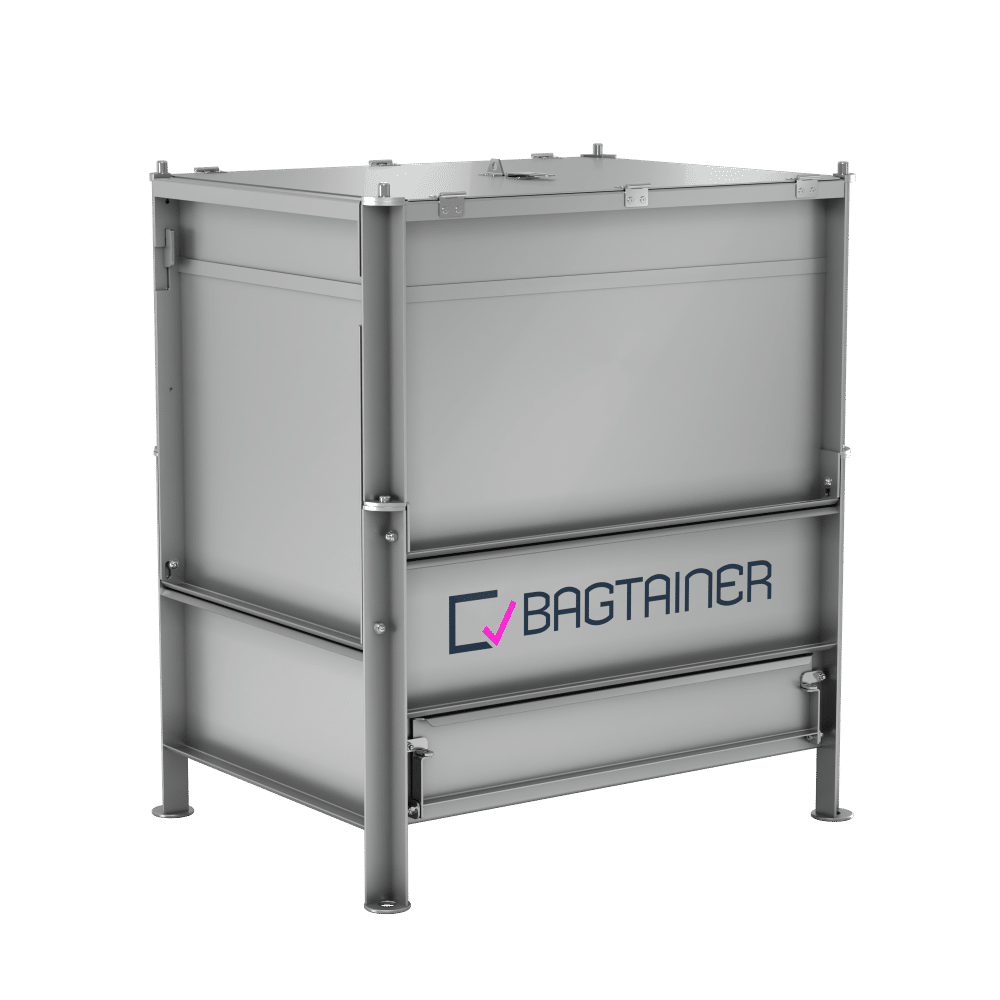

What are bagtainer®?

bagtainer® are stainless steel containers designed for the transport and storage of Single-Use Bags in bioprocess engineering. They protect the sensitive bags and allow for the easy connection to other biotechnological equipment – on a short-term or long-term basis.

Bioprocess engineering: storage and transport perfectly integrated into your process

There are various possibilities to support – or simply not interrupt – the production and transport processes in bioprocess engineering. Our bagtainer® come with the following equipment and options, which serve most applications in biotechnology:

Biotechnological equipment that we regularly combine with bagtainer®:

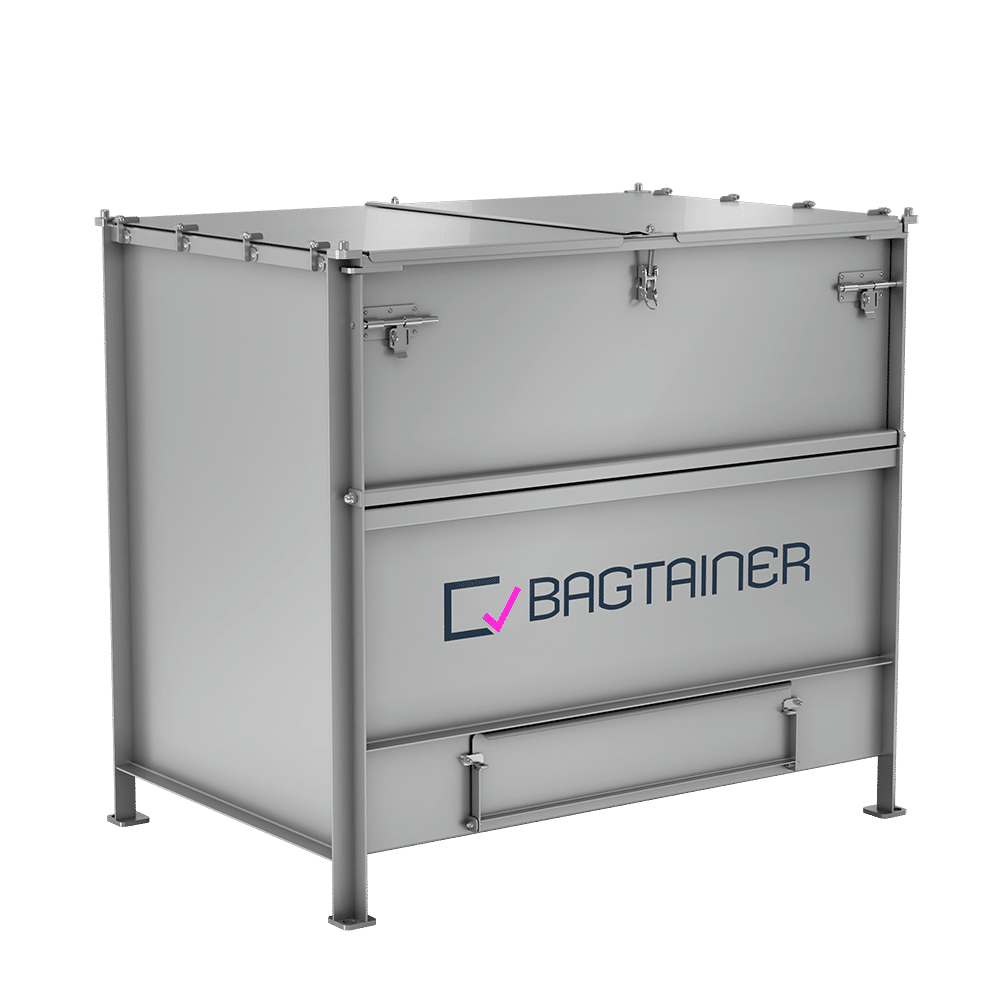

- Heating or cooling equipment: To keep the liquid media in Single-Use Bags cold or warm, the bagtainer® are equipped with sandwich walls. Insulated on the outside, a temperate medium such as coolant is passed through them on the inside. This expansion is operated by an on-site system (such as a heating system or a cooling compressor).

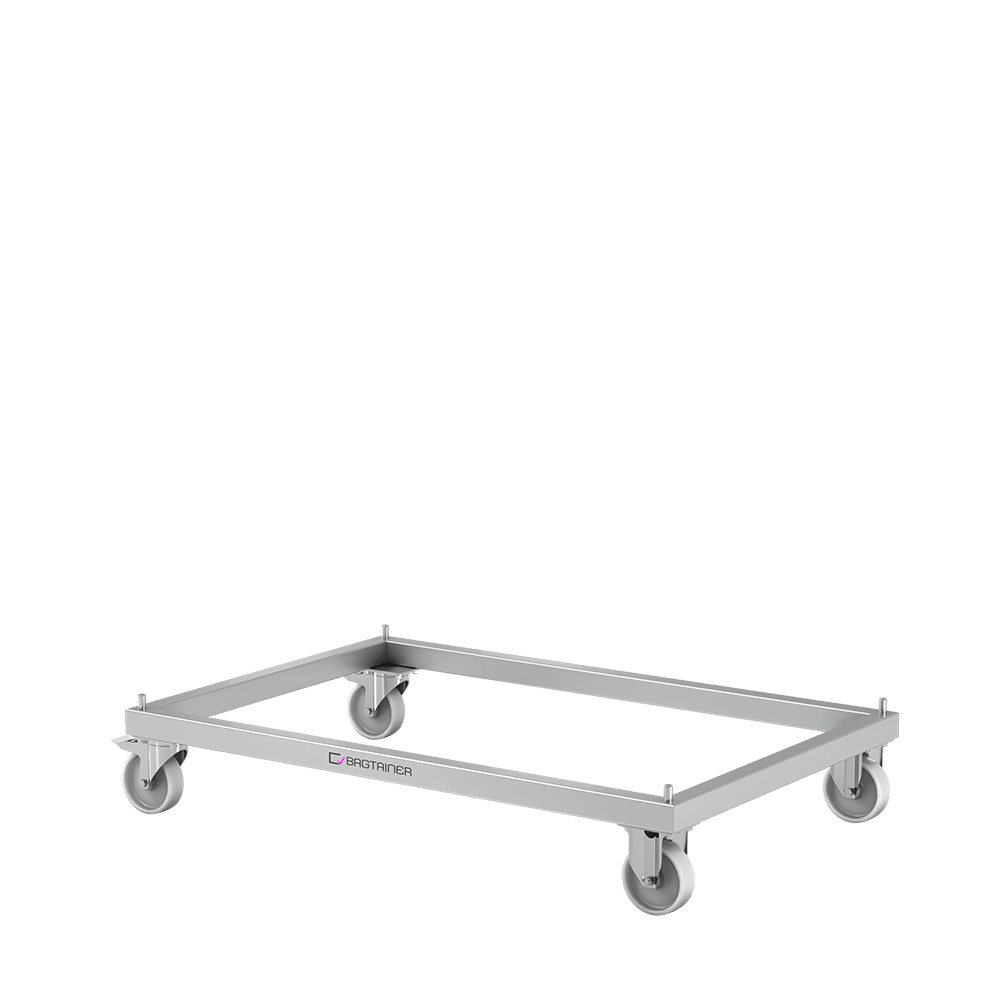

- Mixing equipment: Here, a magnetic stirrer is placed under the bagtainer®. We can install the appropriate stirrers for all common Single-Use Bags.

- Scale: For this option, the bagtainer® is provided with a frame on the underside. The stainless steel load cells are installed on this intermediate level. We have working relationships with all leading manufacturers and can offer you the load cells that are compatible with your systems.

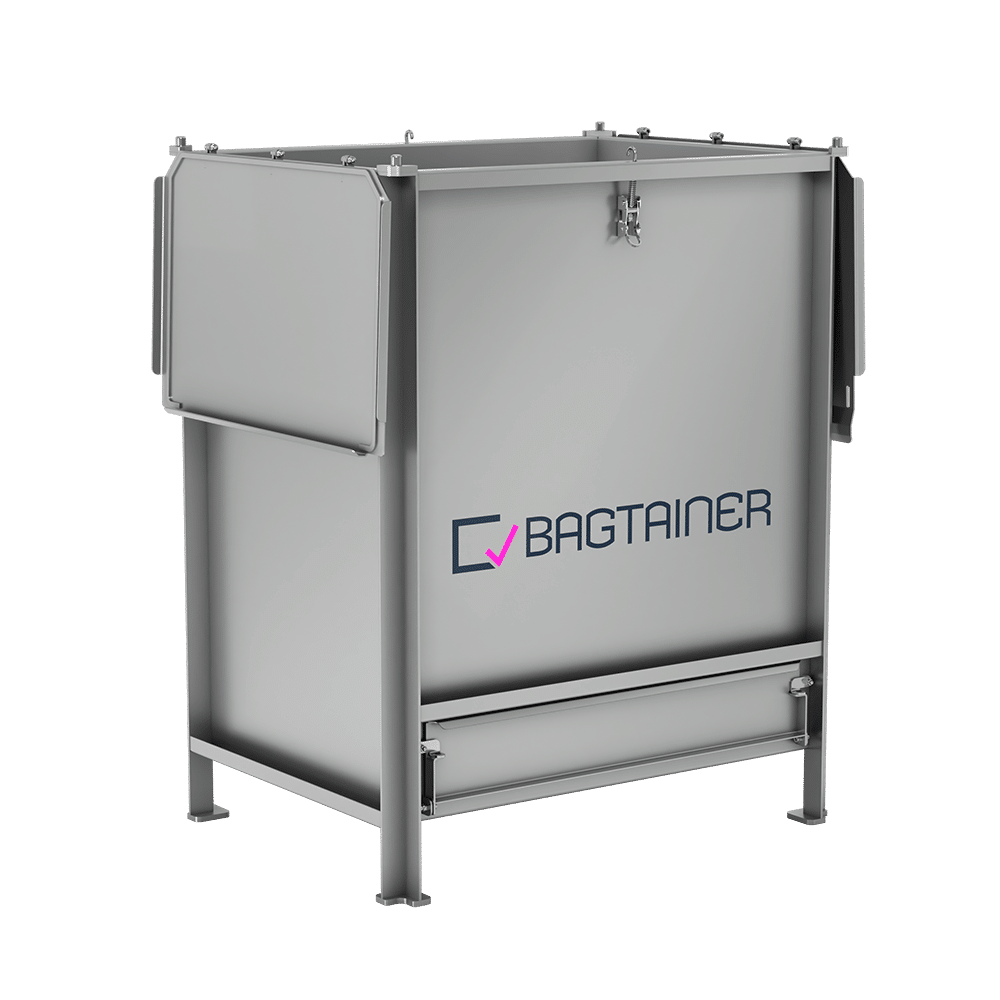

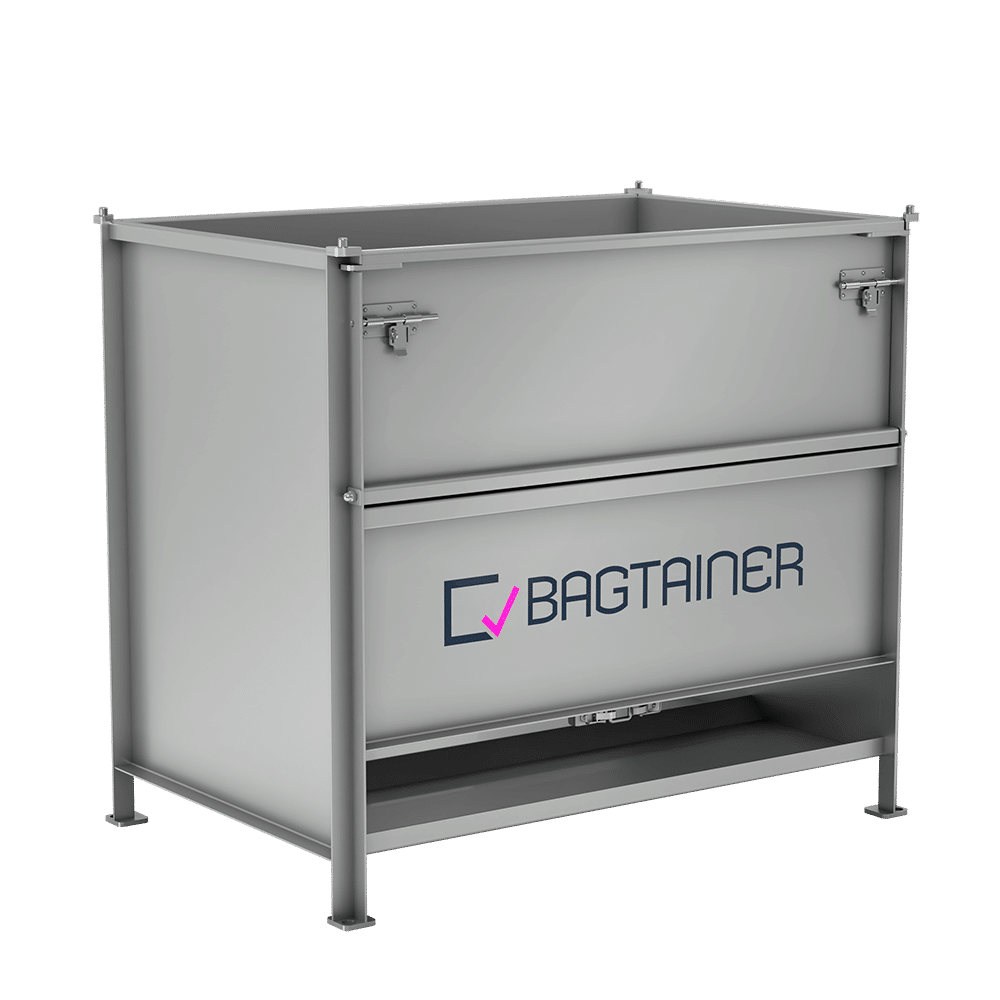

- Folding walls: The walls of the bagtainer® can be designed so that they can be folded to half of their height. This way, all four walls including the side struts can be folded in.

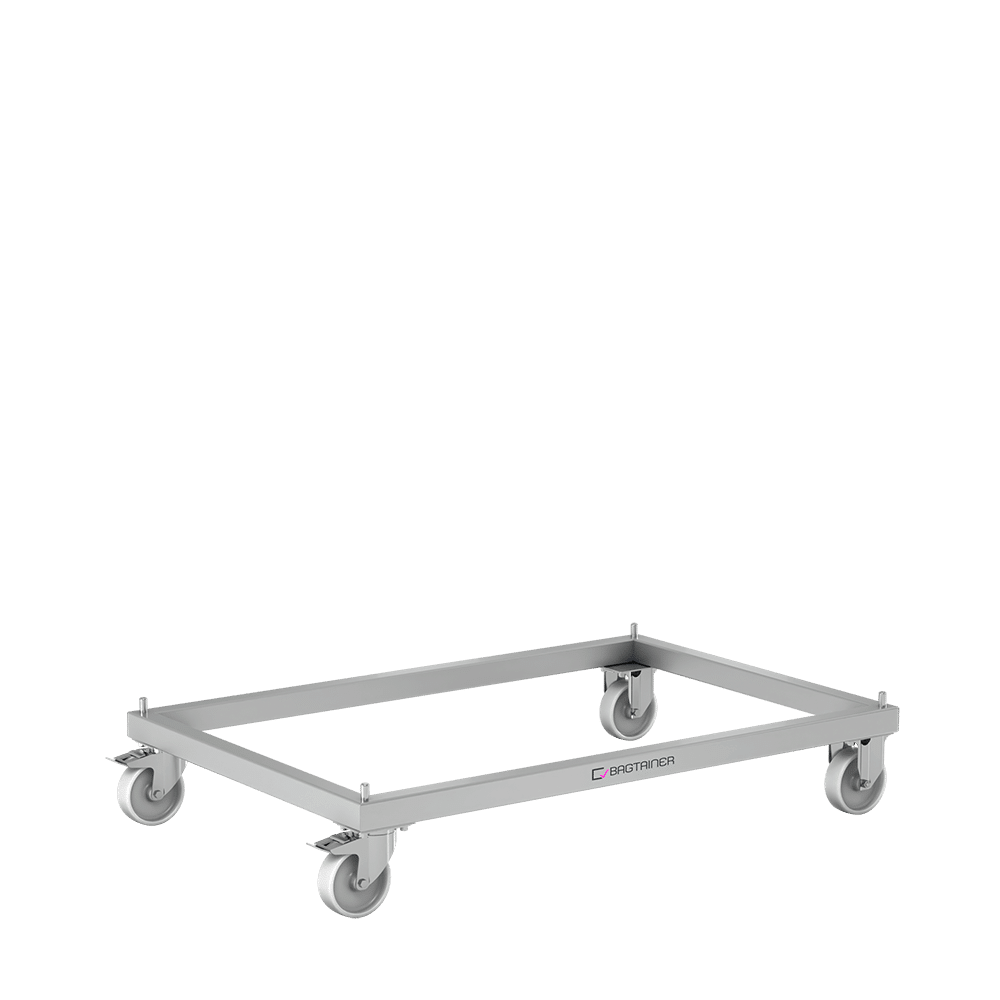

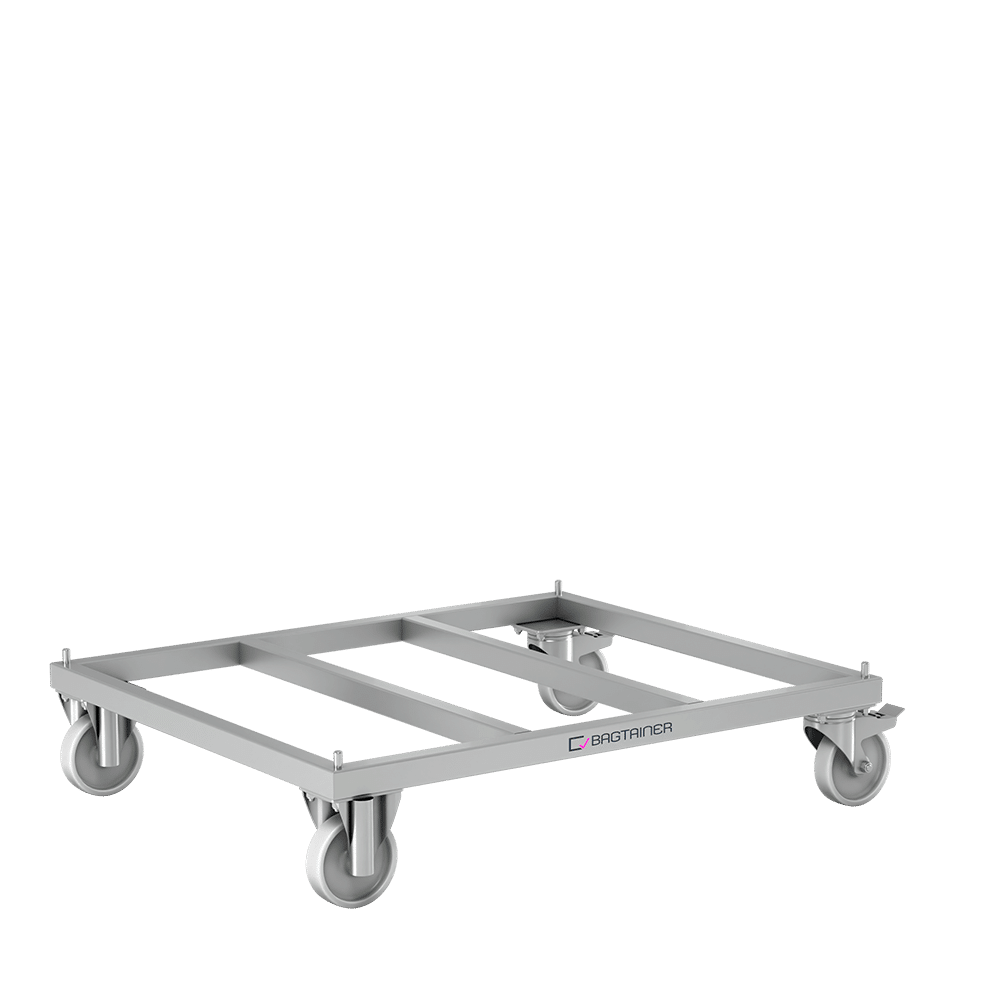

- Mobile frame, trolley and master mover coupling: If you need to transport the biotechnological container without a forklift or pallet truck, you can have a coupling for master mover units fitted, or purchase a mobile frame or trolley.

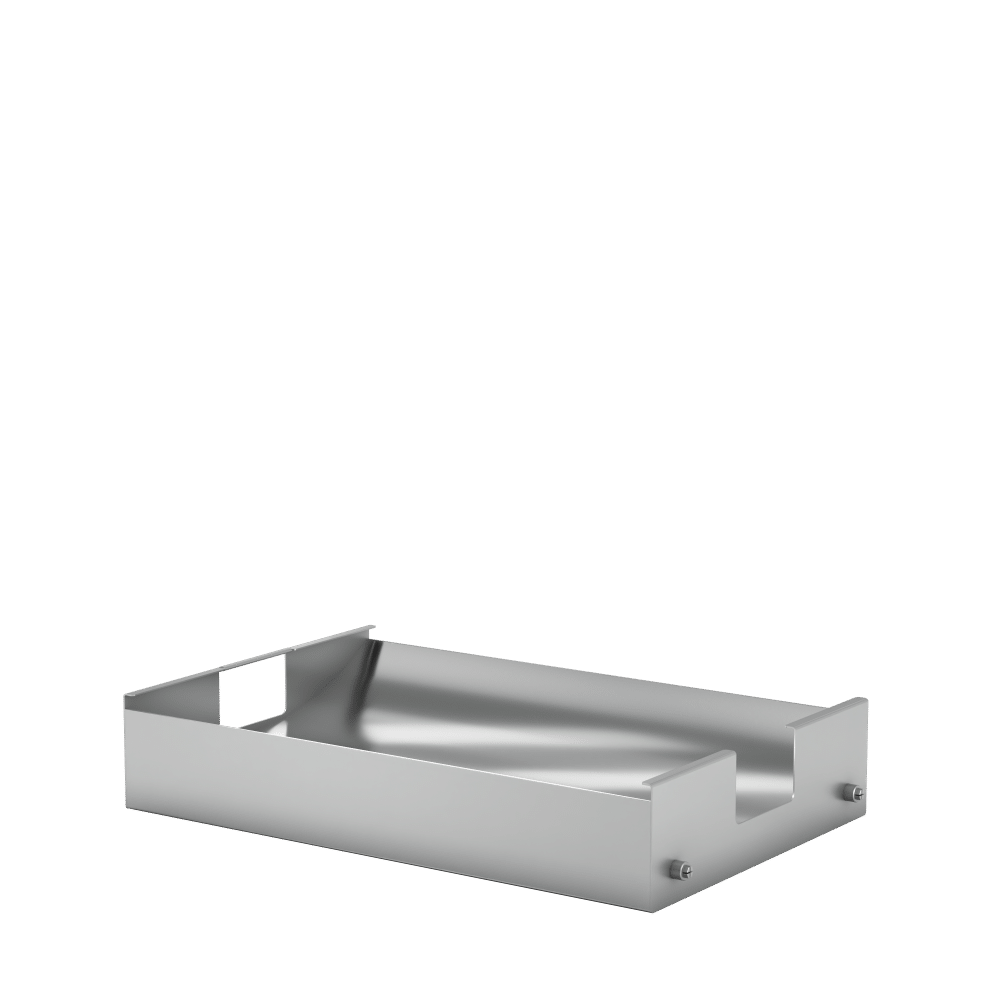

- Hose compartment: The bagtainer® can be provided with a storage space on the underside to protect the filling and removal hoses that are required in bioprocess engineering.

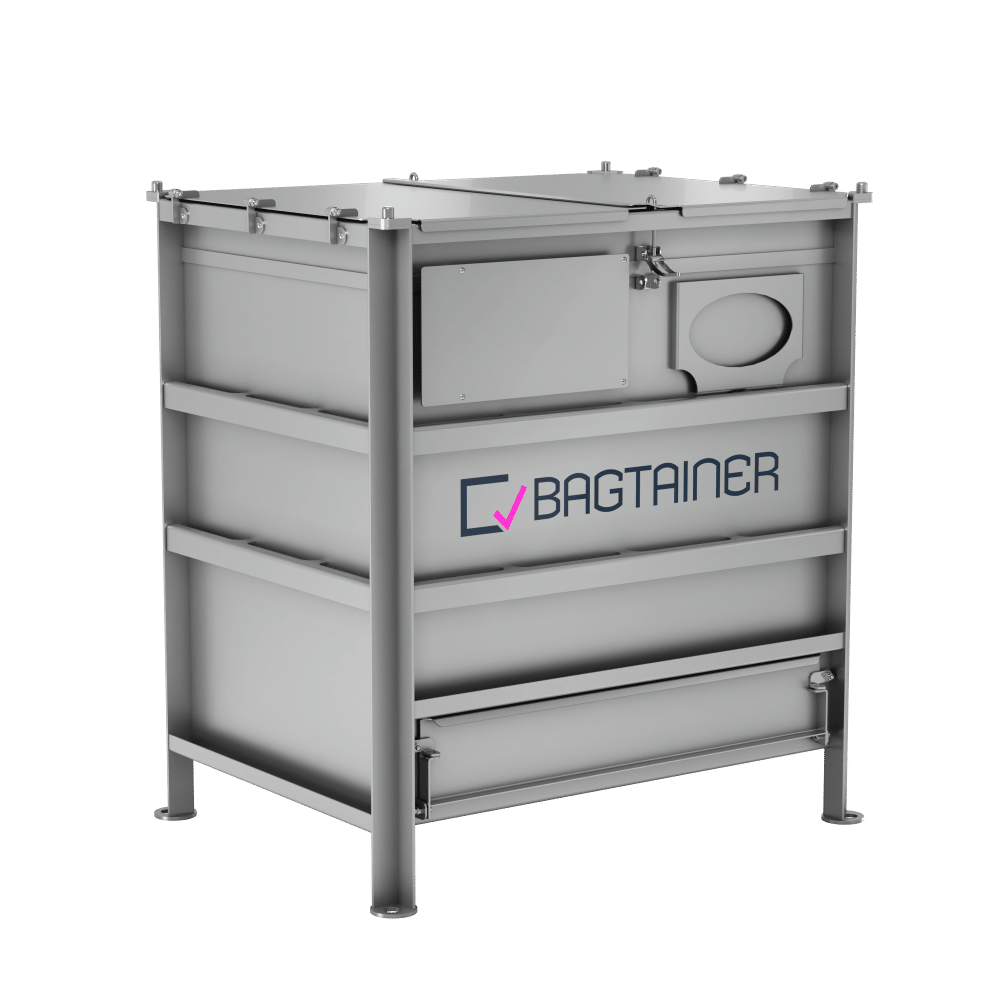

- Inspection window: If you want to keep an eye on the liquid inside the Single-Use Bag, we can integrate an inspection windows into the walls of the bagtainer®.

- Lift systems: Above a certain volume, the Single-Use Bags become difficult to move or even fill by hand. For cases such as this, we are happy to add a manual or pneumatic lift system to facilitate the process.

Good to know: bagtainer® is known for special solutions in bioprocess engineering. The products are crafted in our manufactory and can be modified on request to suit your needs!

Equipping biotechnological containers with additional equipment | bioprocess engineering improved

In order to efficiently connect bagtainer® to pharmaceutical plants and bioprocessing systems, they can be modified with a wide range of options. From cooling equipment to scales and magnetic stirrers, we expand the bagtainer® to meet your requirements and to be easily implemented in your process chain.