Downstream processing in the pharmaceutical industry – biotechnology in a nutshell

Downstream processing is the preparation of biopharmaceutical products following cell cultivation. Any foreign substance is removed, leaving only the active ingredient behind. While upstream processing involves the production of the required substances, the downstream processes focus on transforming the pharmaceutical substance into a viable medicinal product.

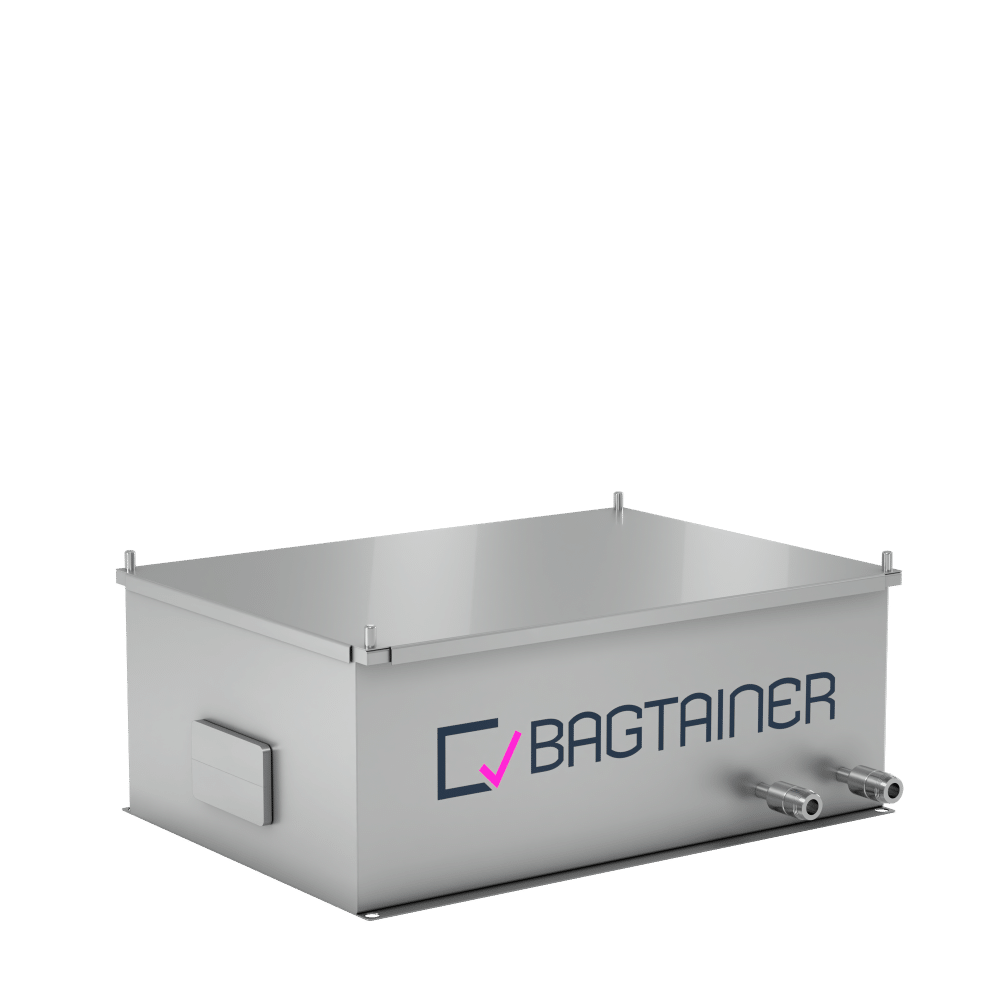

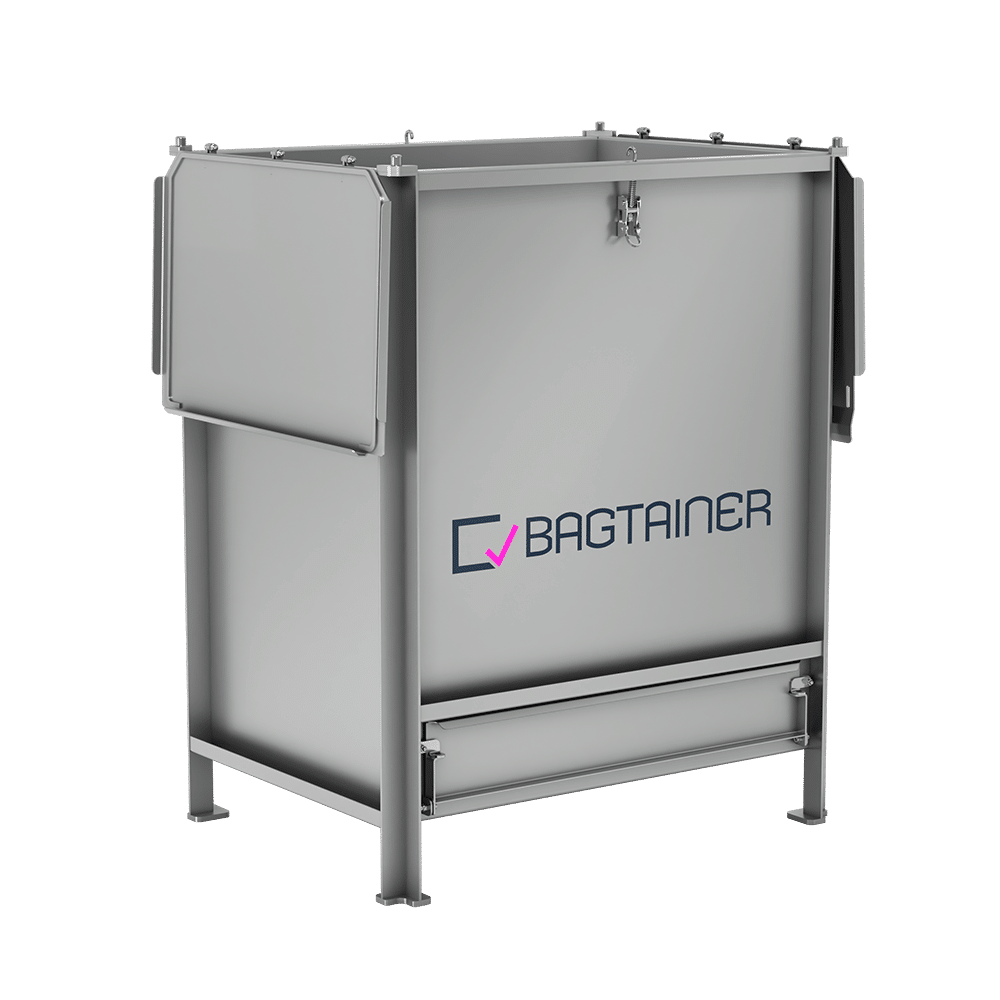

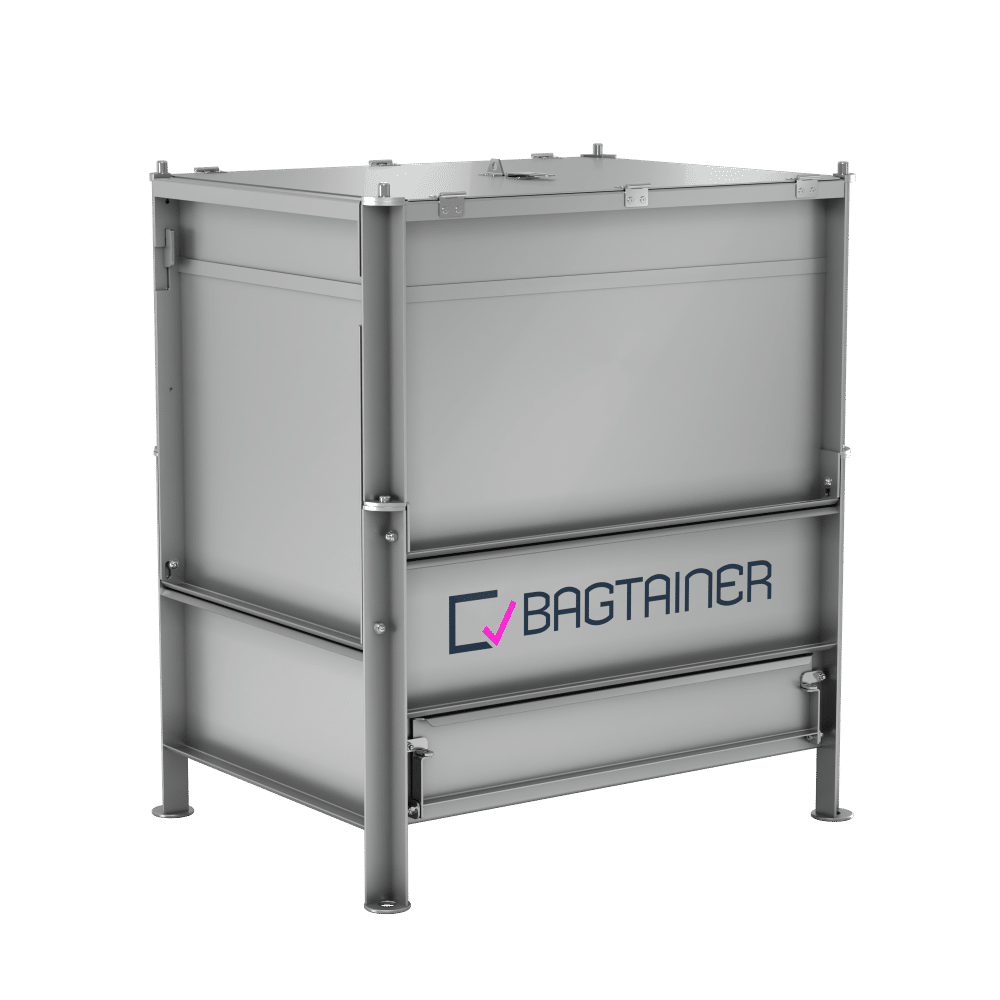

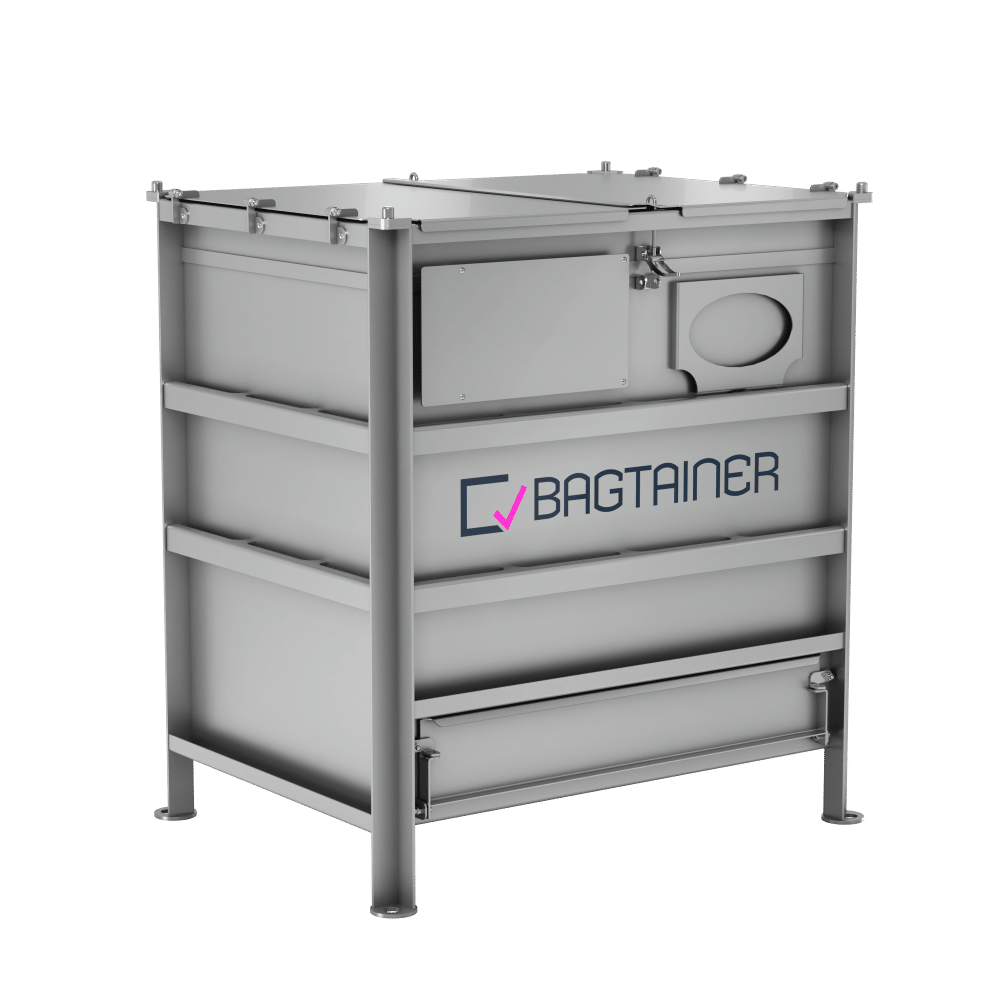

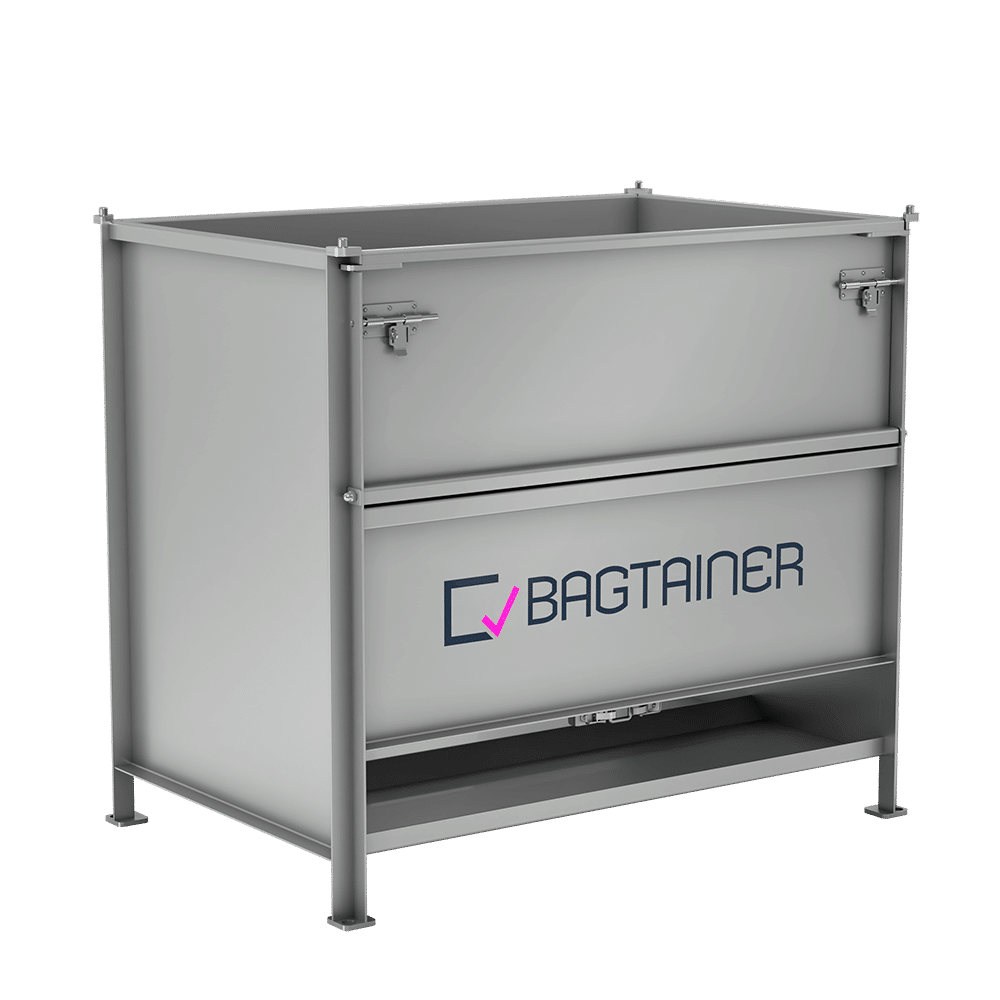

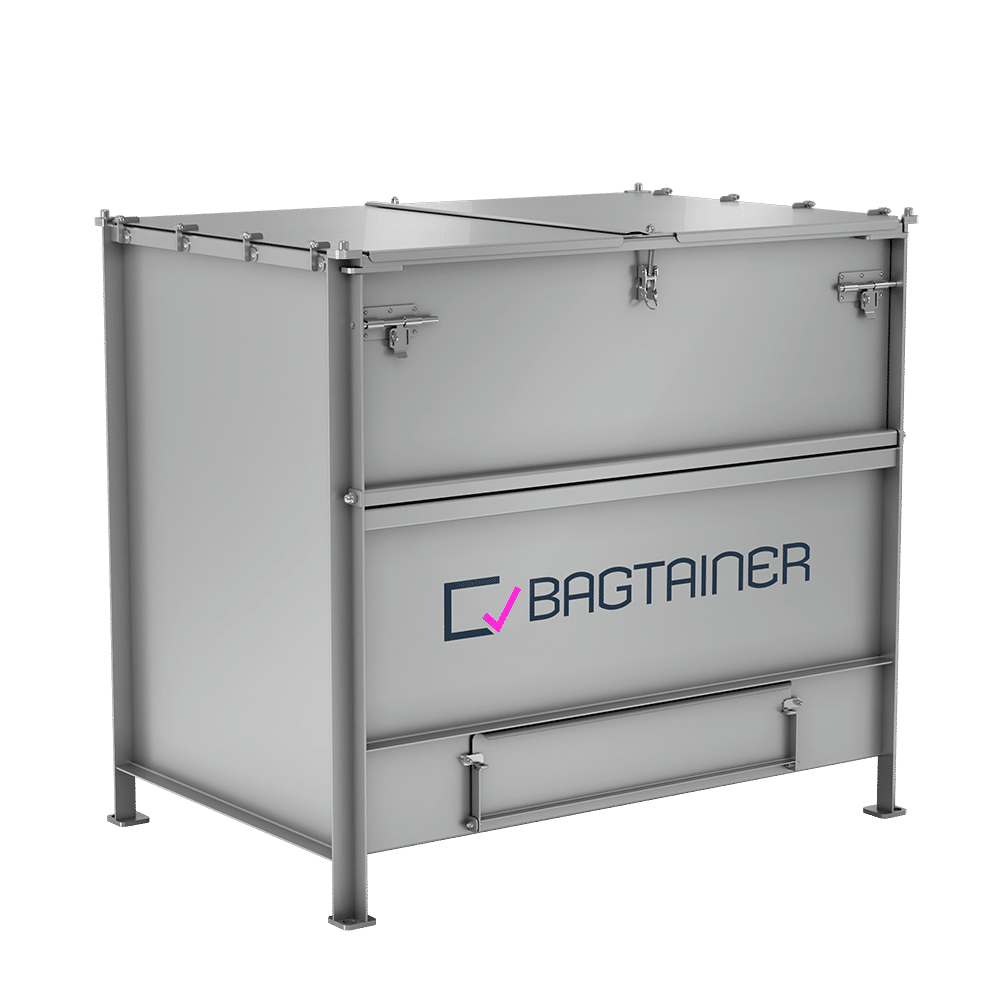

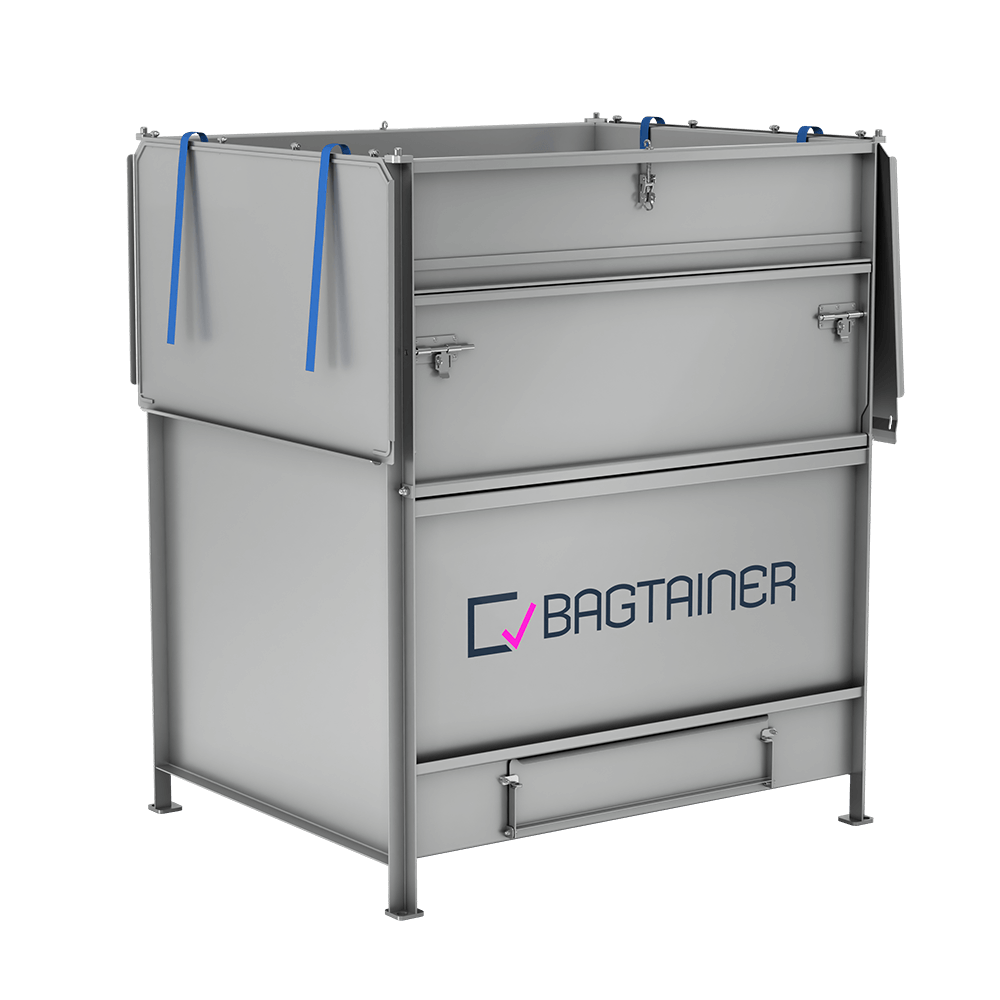

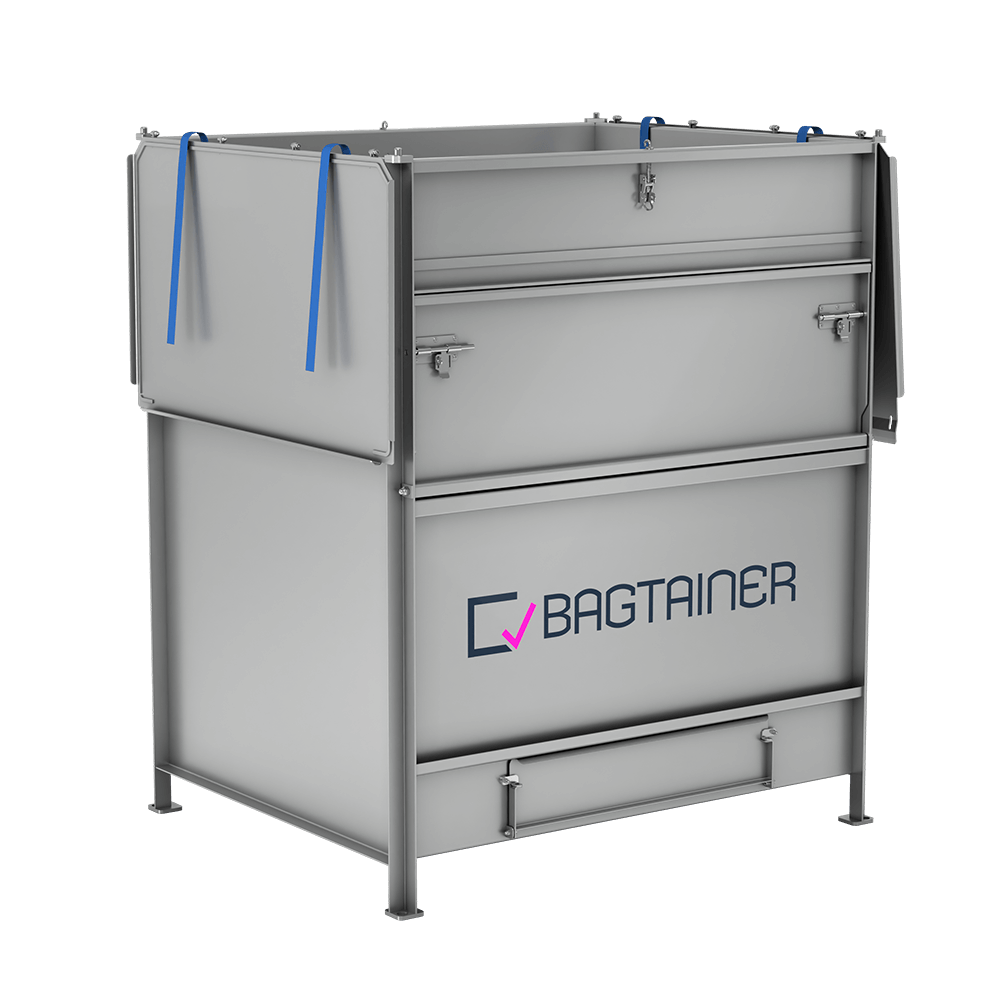

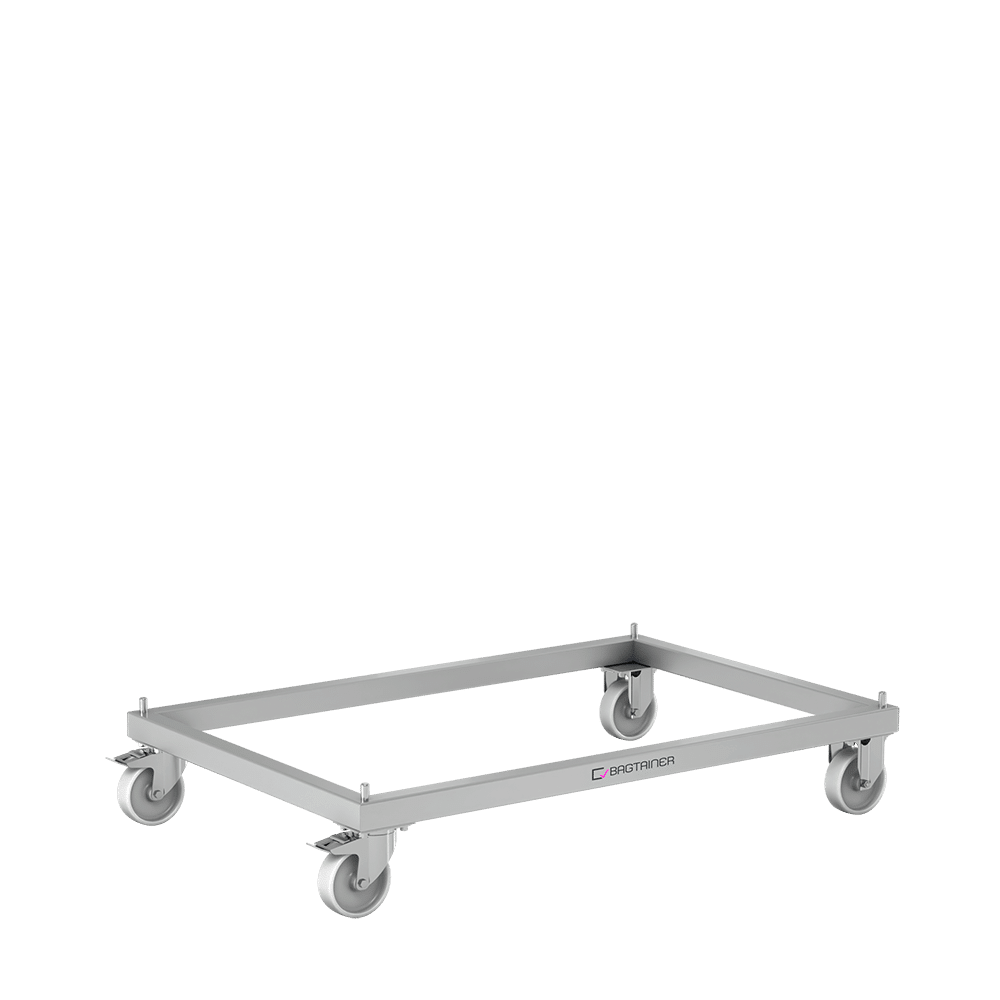

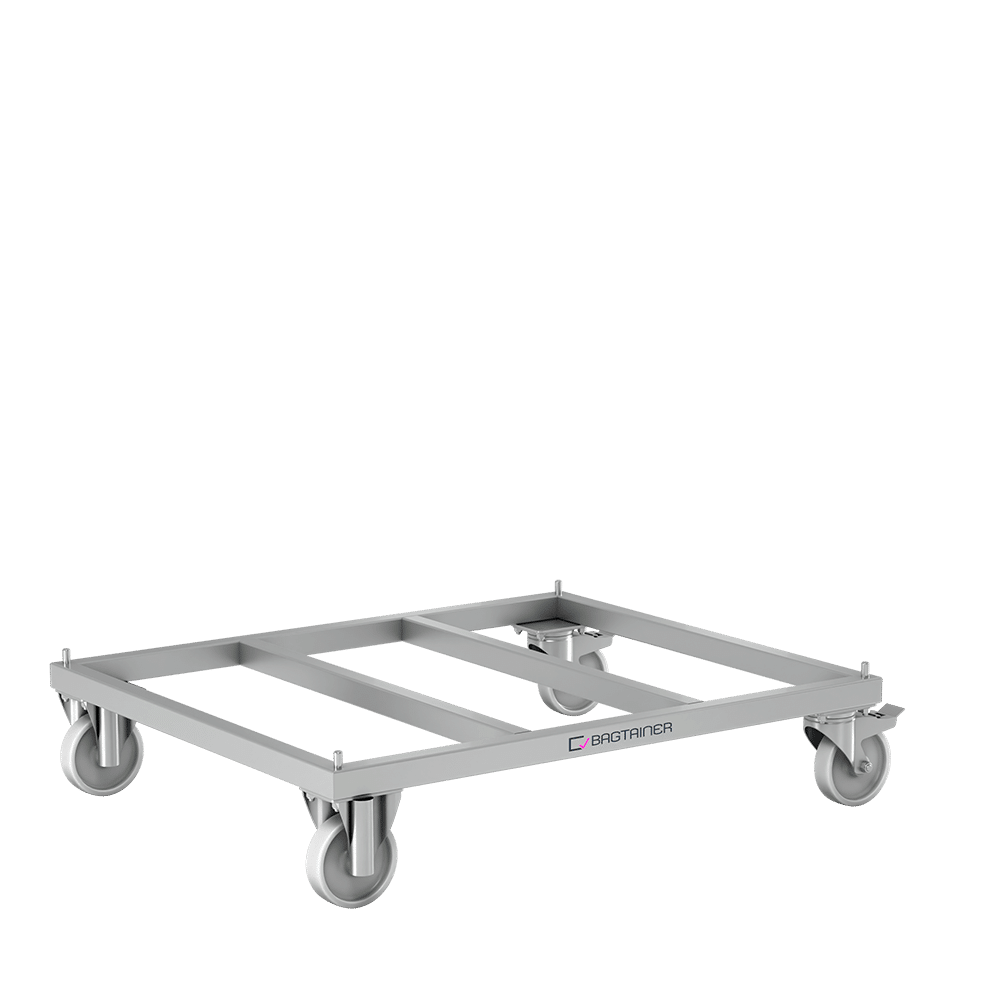

Tip: Our bagtainer® are also suitable for integration into a downstream system. Because they are hand-crafted individually and can therefore be completely adapted to your needs, they are also guaranteed to fit into your production.

Downstream processing: the preparation of pharmaceutical products

In downstream processing, the cell cultures are separated from by-products and waste products as well as the substances that were necessary for cultivation. This requires several steps that make up the average downstream process:

- Fats

- Acids

- Solvent

- Binder

- Preservatives

- Culture media

Downstream processing: harvest and collection

During harvesting and primary collection, the cell cultures are first roughly separated from other substances (including a preliminary purification).Downstream processing: buffer exchange

Pharmaceutical products sometimes require different buffers depending on the downstream processing phase. At this point and in a given case, the solution used is removed and a new one is added.Downstream processing: concentration

During the ultrafiltration phase, the product is separated from diluting substances. The decisive factor here is the size of the pores in the filtering membrane, which separates molecules of different sizes from each other.Downstream processing: purification

In this step of the downstream process, the pharmaceutical product is freed from any remaining impurities. Depending on the type, there are different methods for doing so.Downstream processing: formulation

In the final phase of the pharmaceutical downstream process, the substance produced is transformed into the actual medicinal product – combined with other active ingredients, enzymes, vitamins and the like, and joined with a base so that the result can be taken as a medicine. Note: Nowadays, single-use systems are commonplace both in upstream and downstream, so that neither plant maintenance nor contamination through corrosion etc. complicate the procedure.

Preventing contamination of cell cultures in downstream processing

As mentioned above, upstream processing can lead to impurities in the product, which then have to be eliminated during the downstream process, specifically during purification. These include, among others:

- Bacteria: After production, the end product is purified with filters that do not even allow particles as small as 0.1 µm to pass through – which includes bacteria.

- Fungi: Fungi are similarly removed with the help of a process known as ultrafiltration.

- Viruses: If possible, viral loads are removed by thermal or chemical methods. As the end products are usually sensitive themselves, chromatographic means or nanofiltration are usually the preferred choice.

- Vitamins: These can often be removed chromatographically.

- Lipids: They occasionally remain after the bioreactor has been cleaned. Chromatographic methods can help here.

- Foreign DNA: Sometimes, marker DNA needs to be actively added as a control agent. It can be removed by nuclease.

Downstream processing: the manufacture of pharmaceutical products

In the pharmaceutical industry, downstream processing is the last step in drug production. Purification of the substances produced in the upstream process creates active ingredients and substances that become medicinal products, some of which are essential for life.

You are working in the pharmaceutical industry and would like to know more about our Single-Use Bag containers? We will be happy to answer your questions and advise you!