Single-Use Bags and their possibilities – what bagtainer® protect

Single-Use Bags – sterile bags used in biopharmaceutical process chains – offer safety when storing or transporting liquids and powders. Disposable solutions are becoming increasingly popular in the pharmaceutical industry – as a cheaper and energy-saving option that poses no risk of cross-contamination in comparison to stainless steel and glass. This eliminates the need for CIP (Cleaning in Place), which is why the bioprocessing bags have become indispensable in today’s production of medicines, buffers and the like.

Single-Use Bags for biopharmaceutical use – interesting facts

Single-Use Bags in biopharmaceutics and biotechnology are used for handling bulk liquids – this covers a wide range of processes:

- Storage

- Transport

- Sampling

- Cell cultivation

- Freezing or cooling procedures

They are already sterilised by the manufacturers, usually with beta or gamma radiation that destroys the DNA of the germs and consequently eliminates any contamination. From antibodies to enzymes to proteins, any substance can be handled at your convenience.

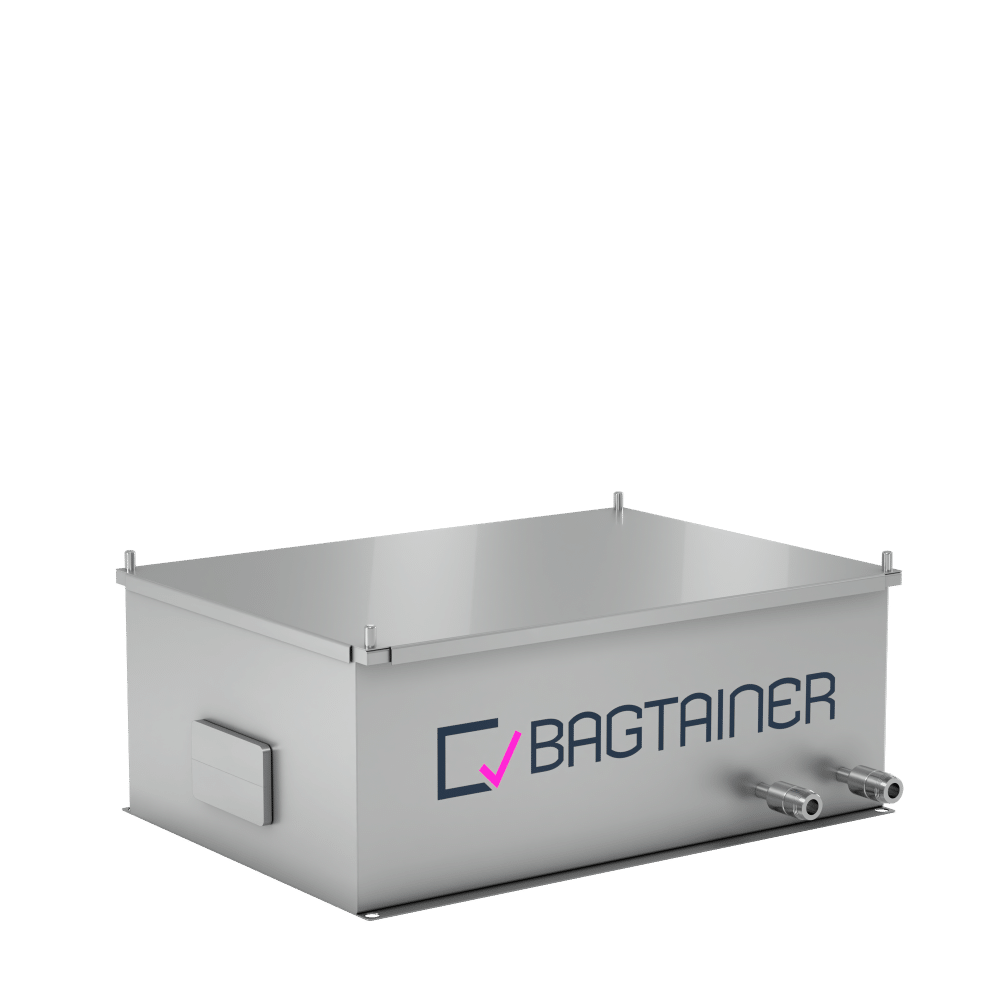

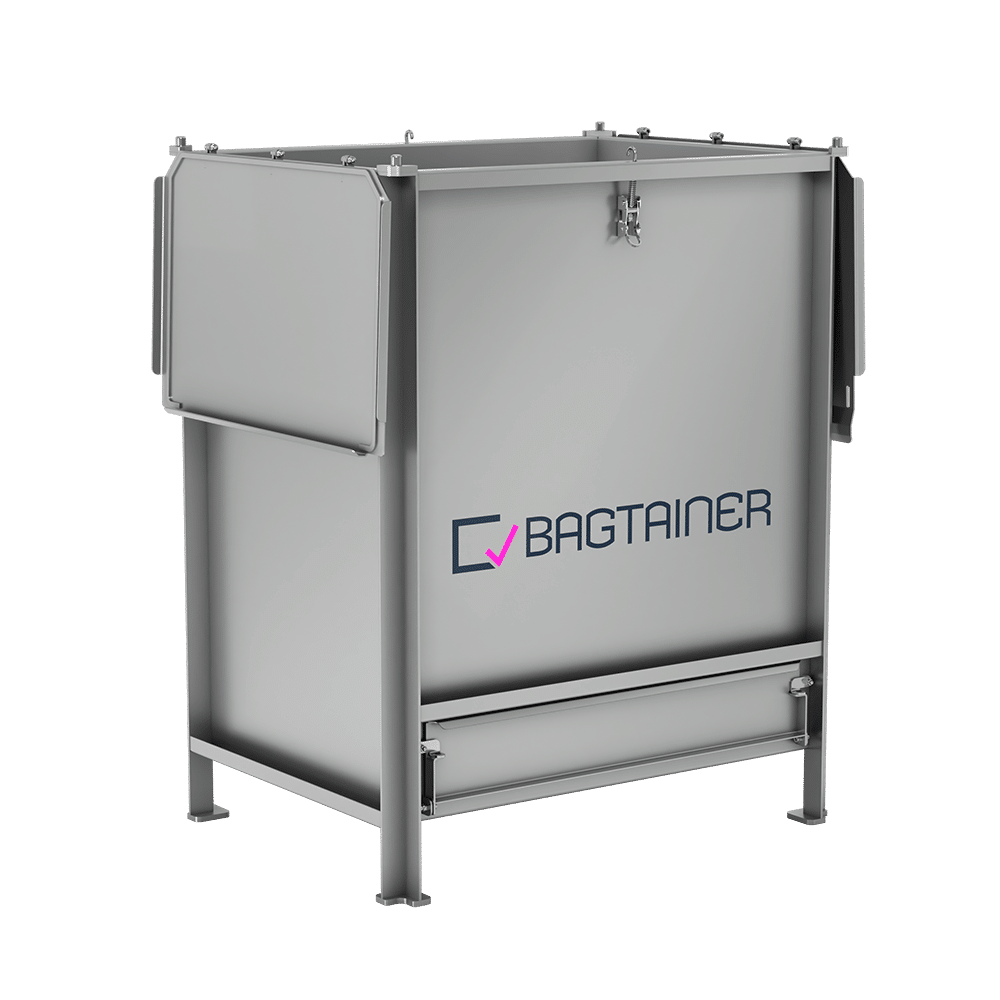

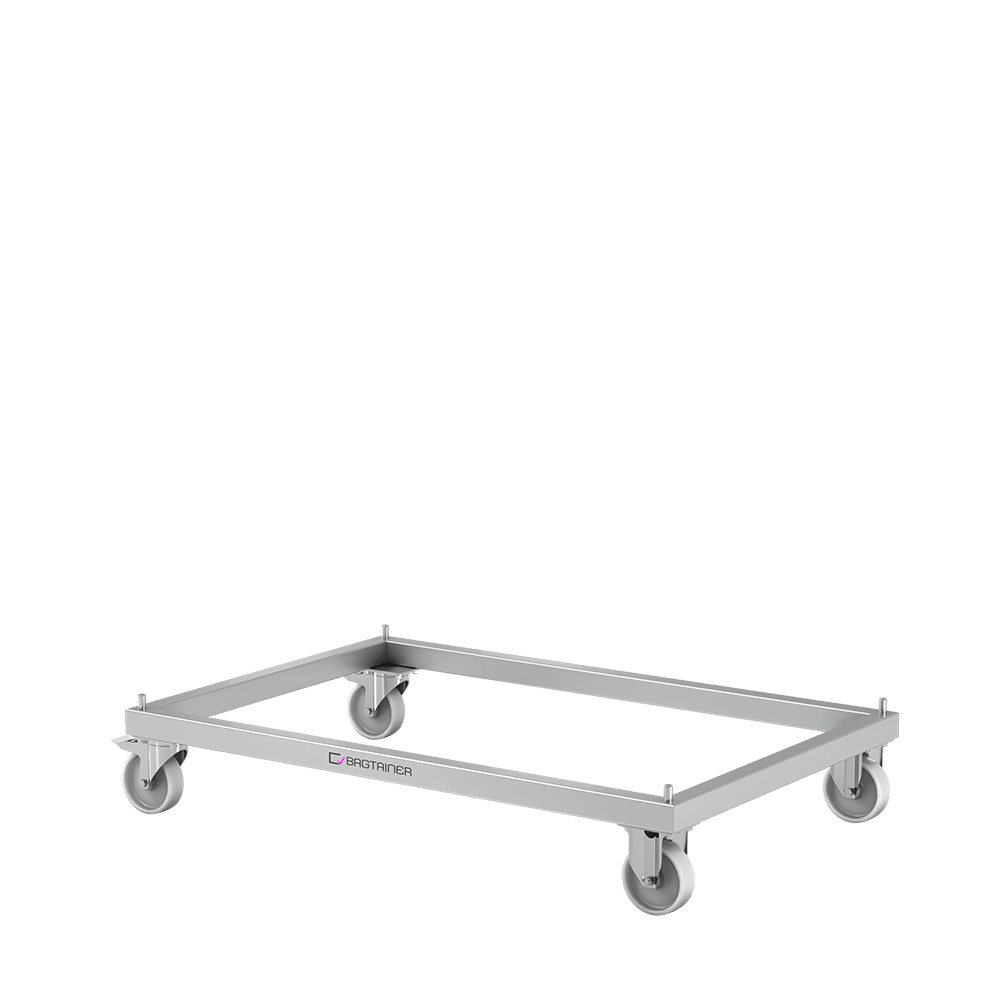

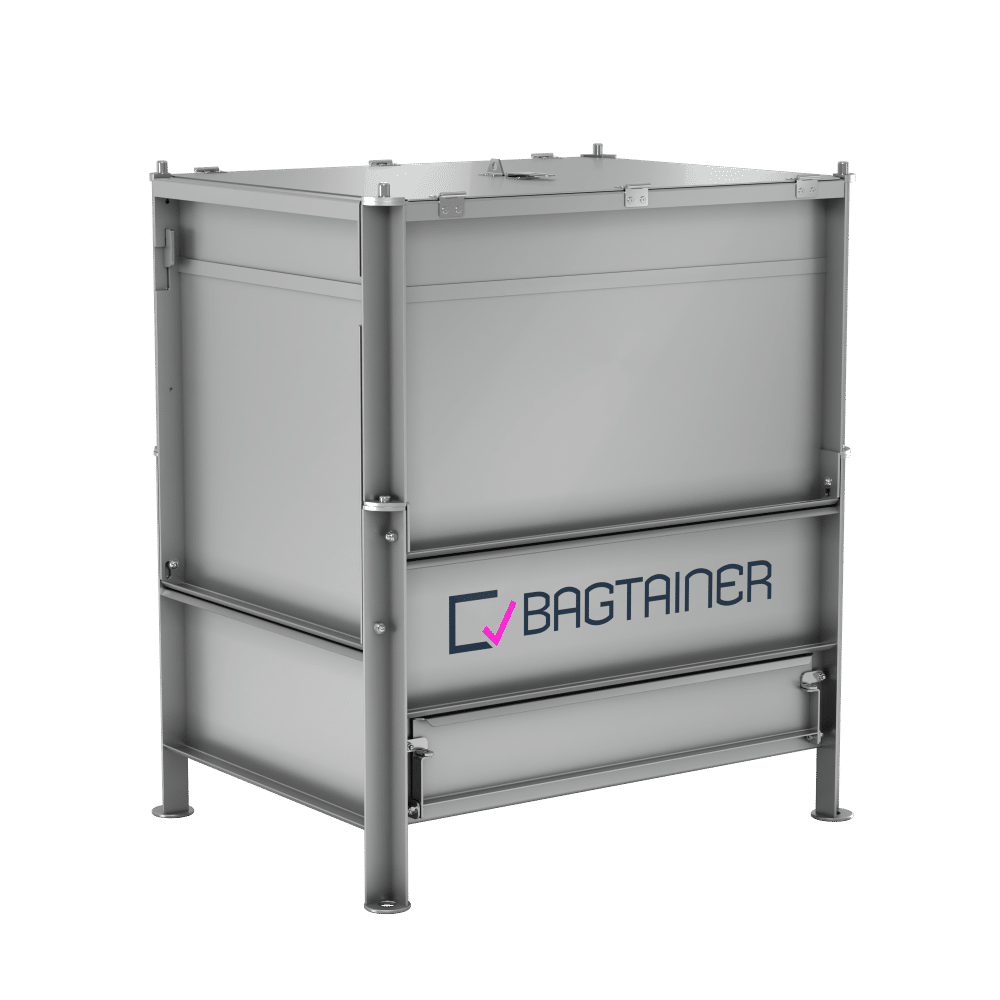

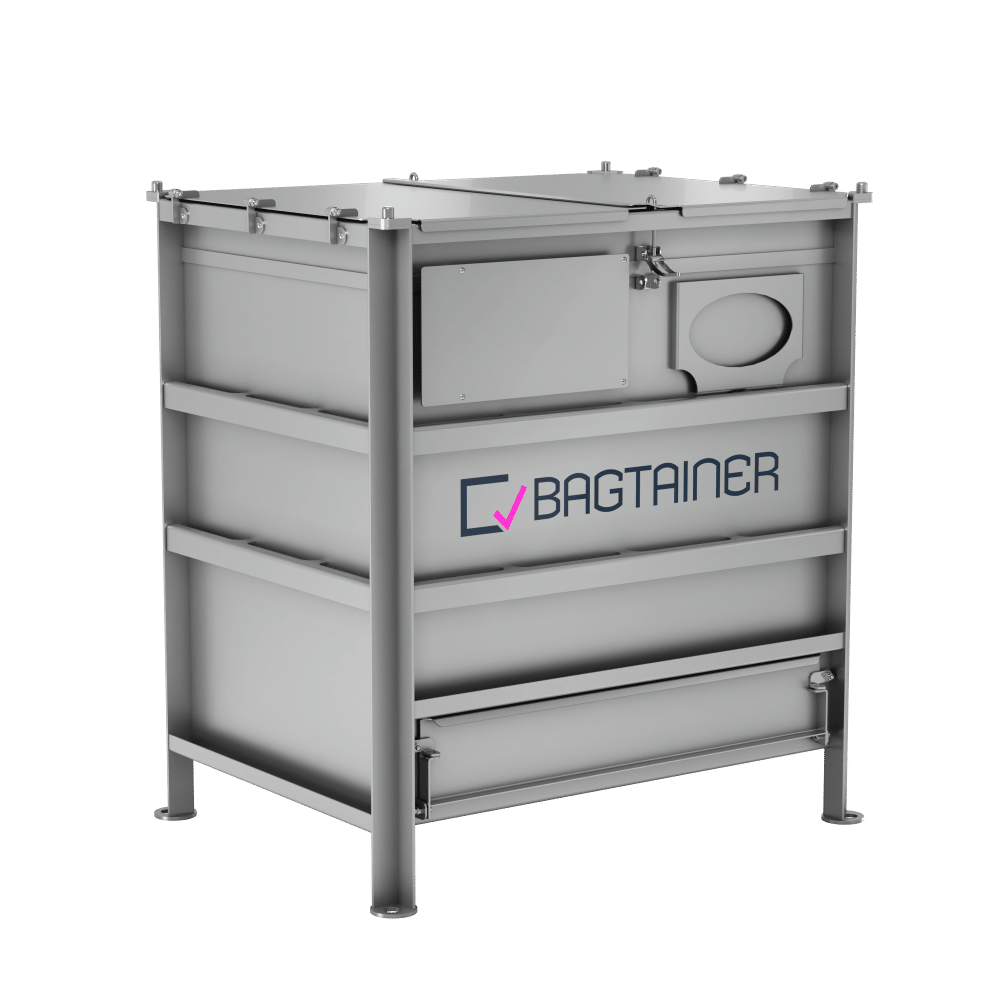

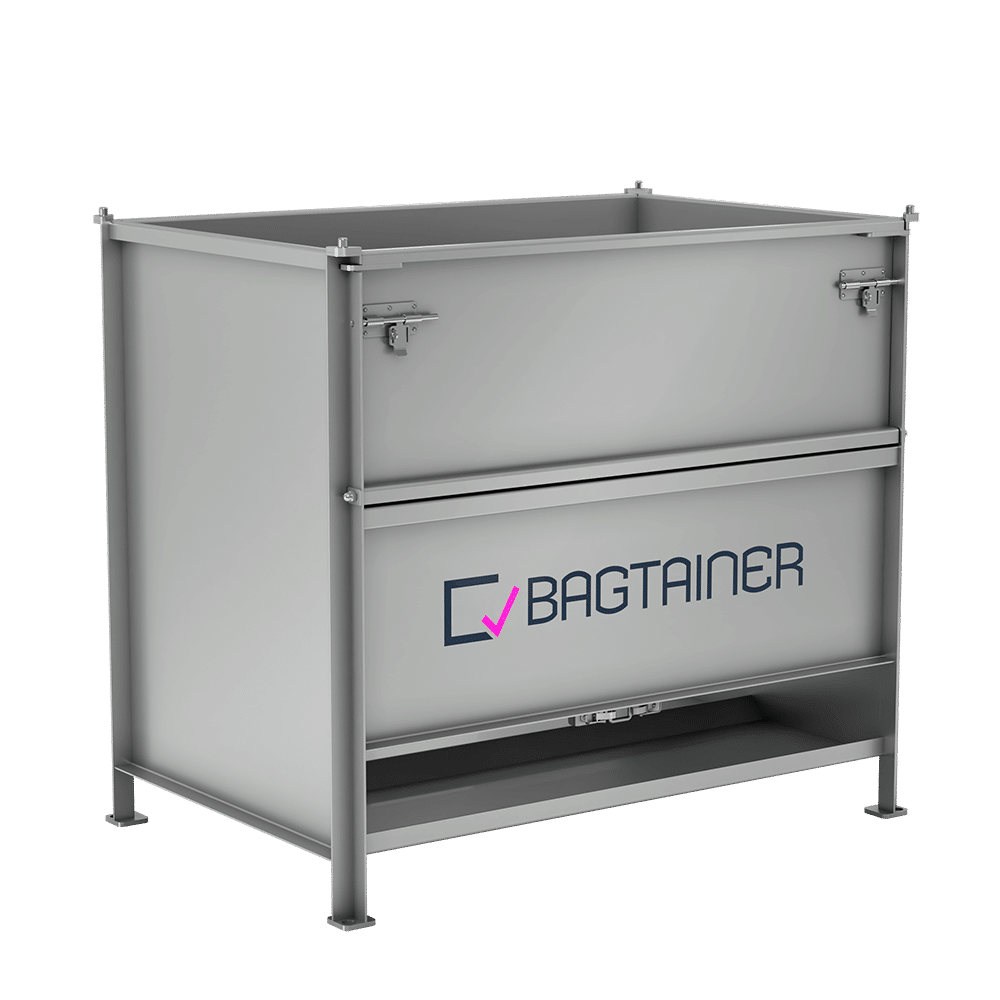

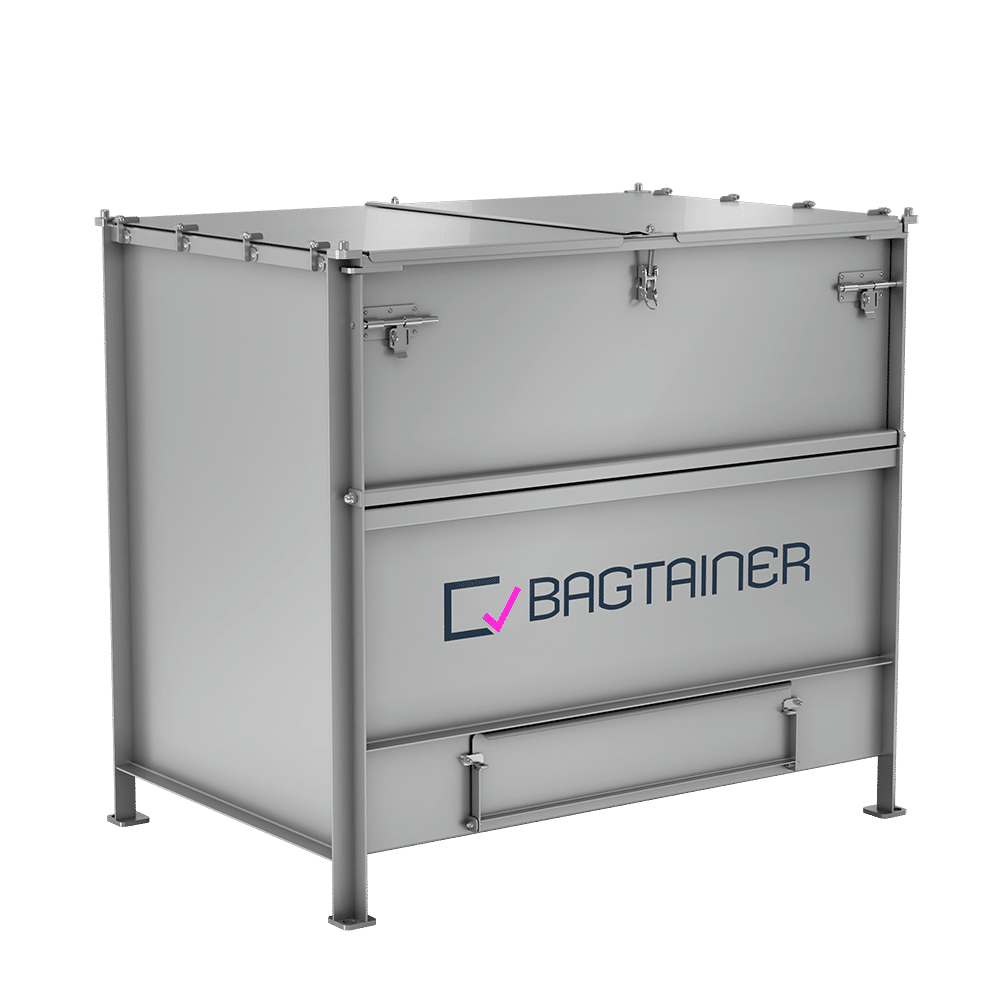

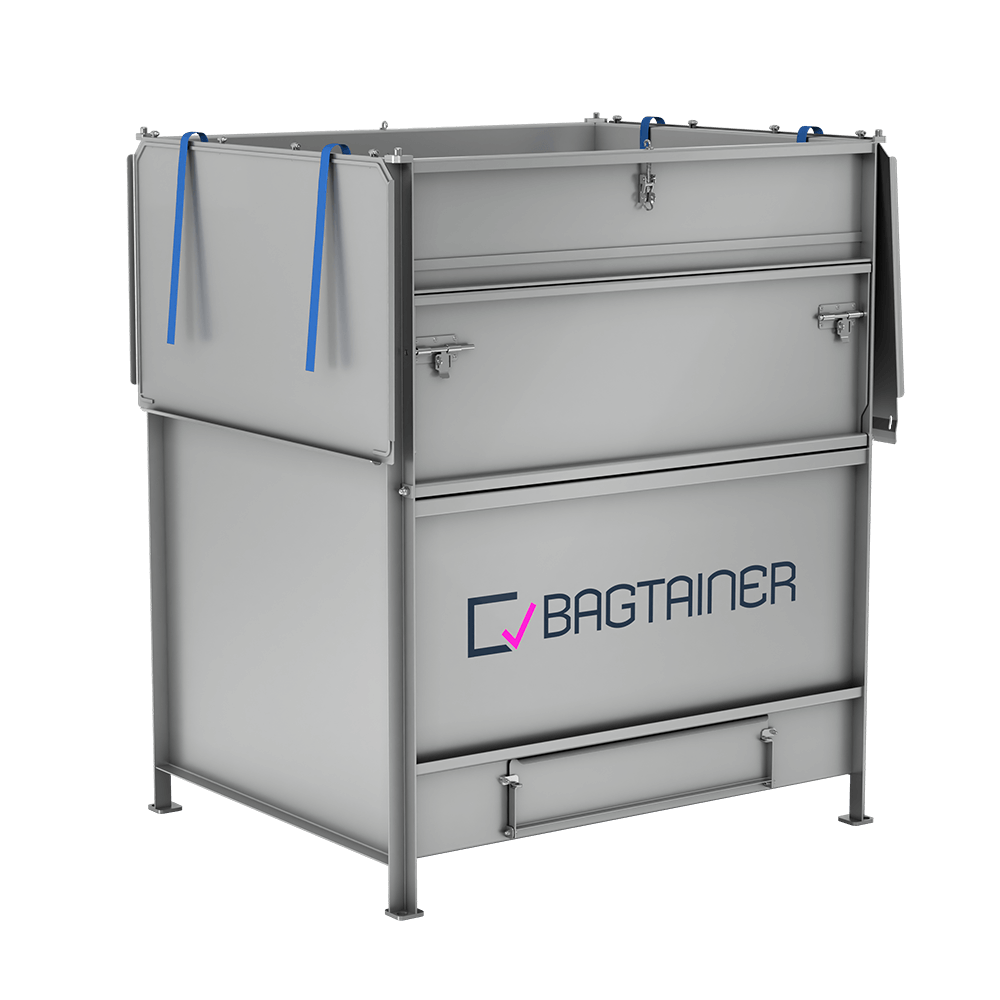

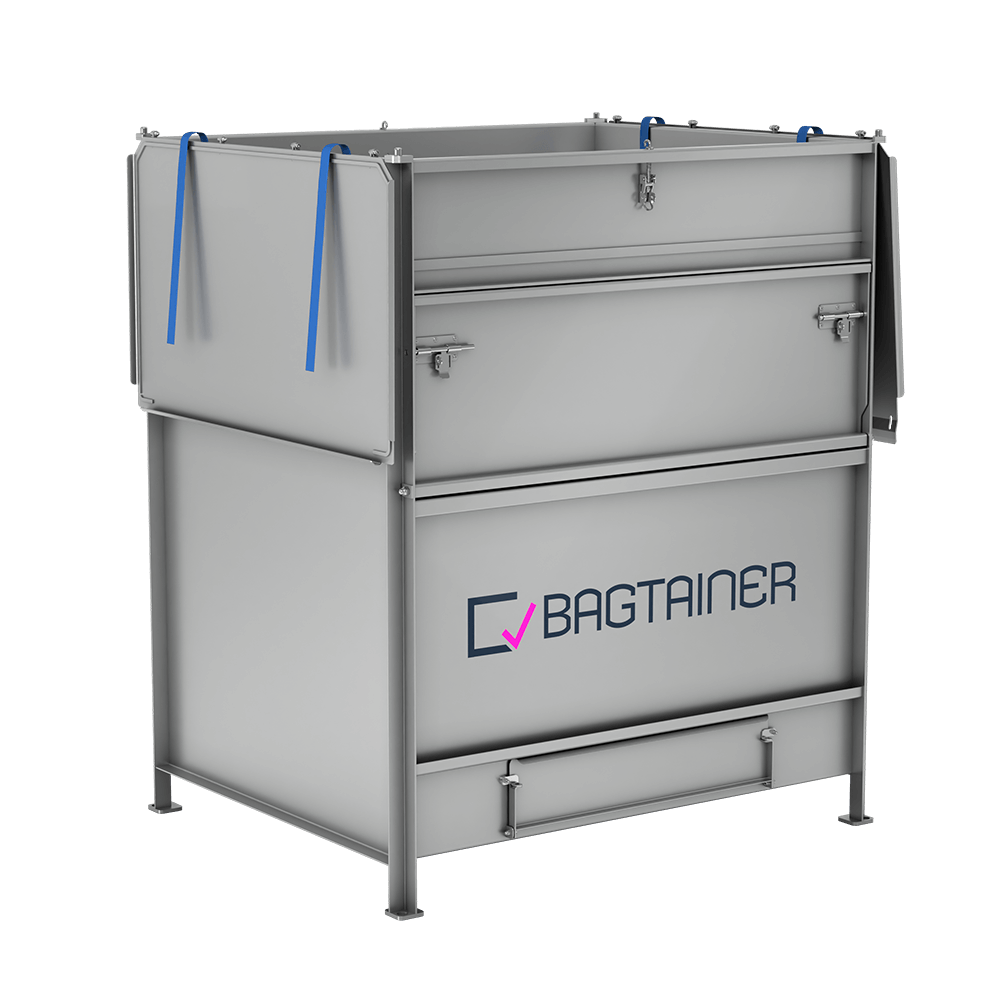

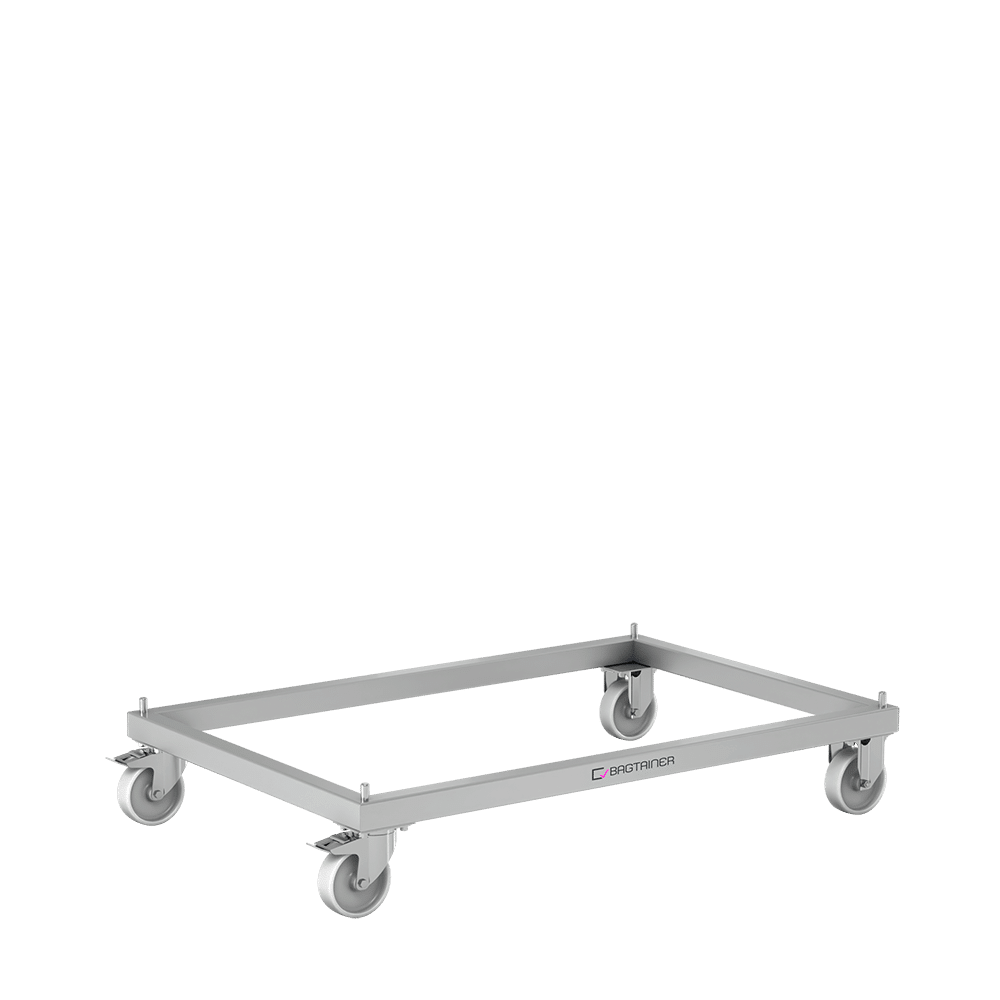

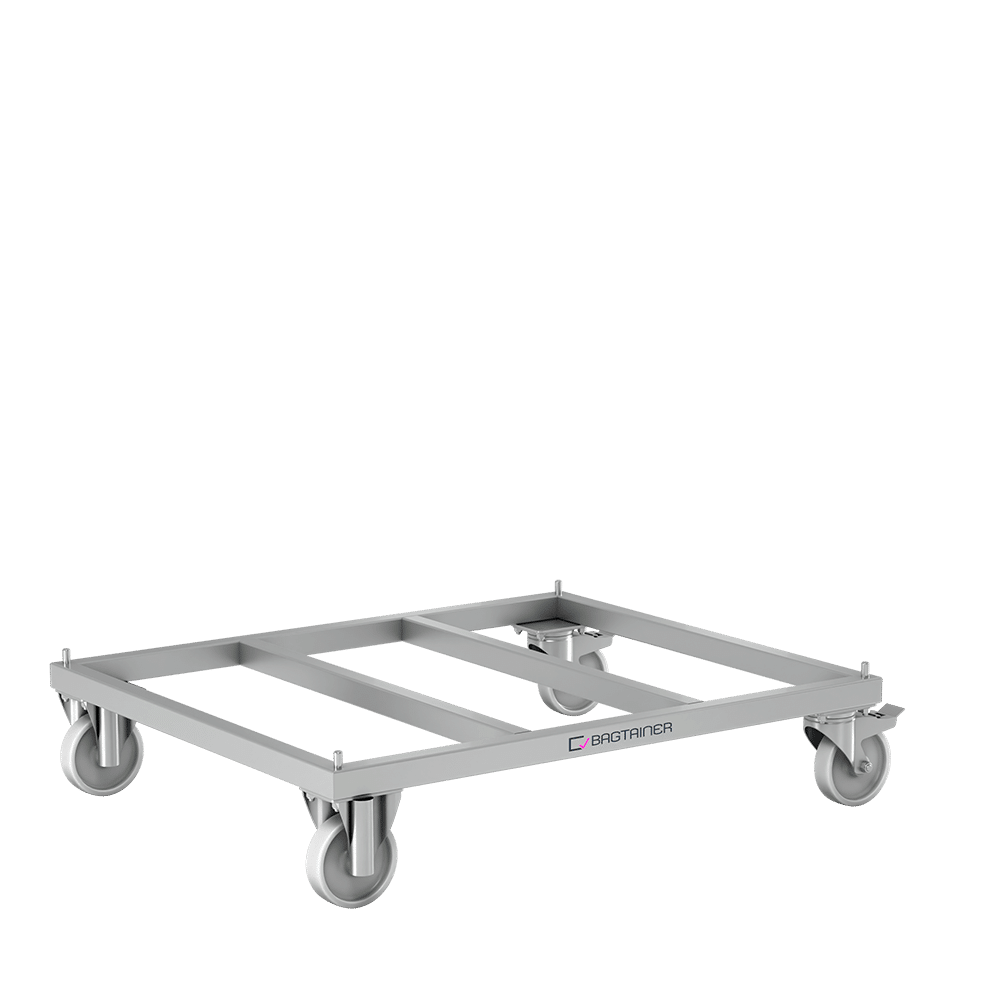

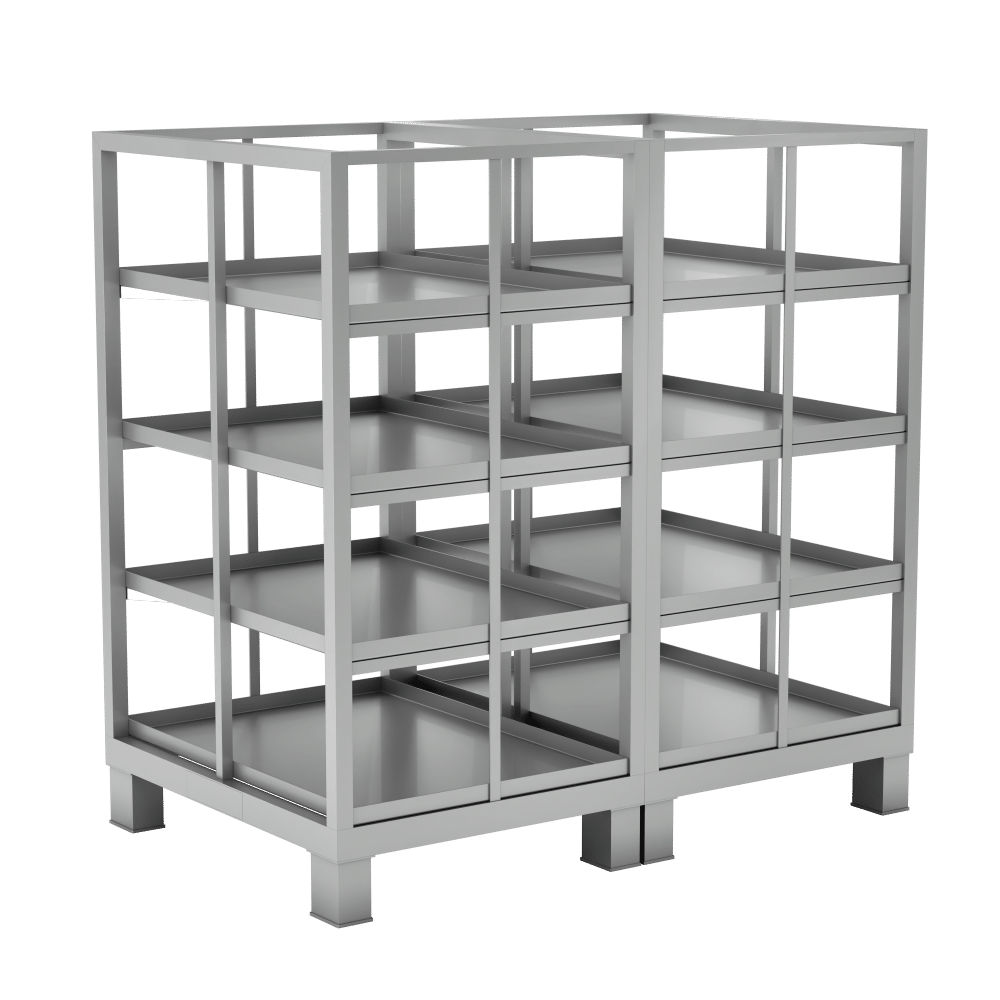

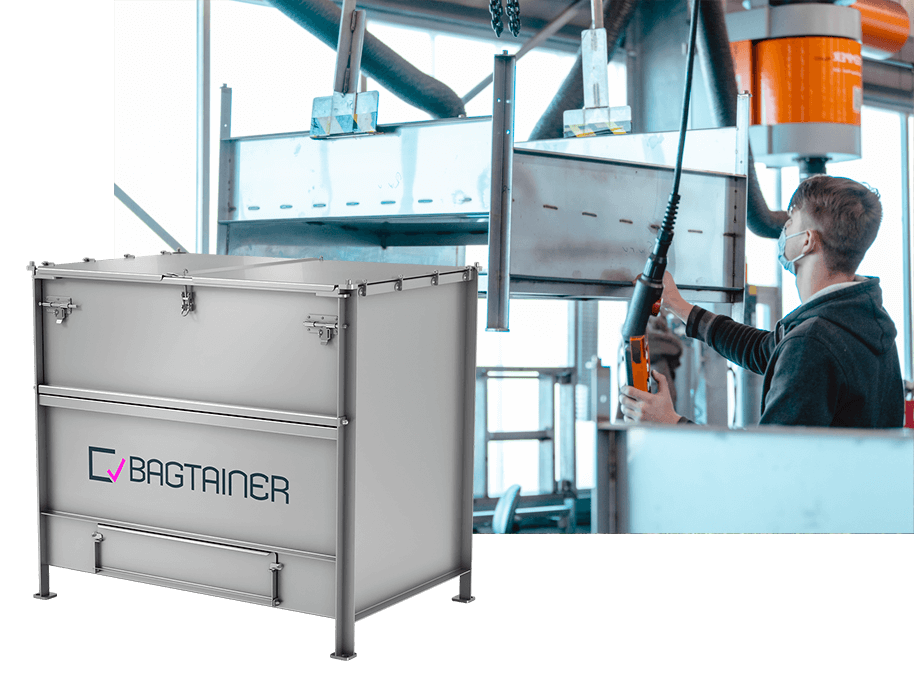

Note: By the way, the bioprocessing bags are rarely stored or transported on their own. Instead, they are placed in “bag handling systems” – containers made of stainless steel or plastic that protect the thin bag. These are exactly what bagtainer® produces – we are also happy to customise special solutions for you in our manufactory.

Types of Single-Use Bags

Single-Use Bags usually come in two different versions:

2D:

- Comparable to a pillow in terms of shape

- Holds between 50 mL to 50 L

3D:

- Varies in shape, often rectangular

- Usually provides more port options

- Holds up to 1000 L

The production of Single-Use Bags

The production of bioprocessing bags consists of two stages:

- Foil production: For this, polymer granulate is melted and pressed flat.

- Bag production: Next, the film is cut and sealed – in a completely sterile procedure. Ports are added as well.

Each stage proceeds in aseptic conditions and in a cleanroom. In between, the product is inspected and sterilised repeatedly.

Note: Single-layer bioprocessing bags are usually produced for storage and transport. Cultivation, however, requires multi-layer bags. Here, the film layers are usually separated by a thin gas layer, which often consists of ethylene vinyl alcohol (EVOH).

Bioprocessing bags – the advantages of Single-Use systems in sum

Single-Use Bags are the standard in biopharmaceutics today. For good reason:

- Safe and sterile

- Available in numerous versions

- Always customised to your needs

- Inexpensive and effective

- Versatile

- Can be integrated into process chains